In today’s fast-evolving world, the construction industry must keep pace with rapid urbanization, climate change, resource constraints, and increasing demands for speed and sustainability. Traditional construction methods—slow, labor-intensive, and often inefficient—are no longer capable of meeting these challenges.

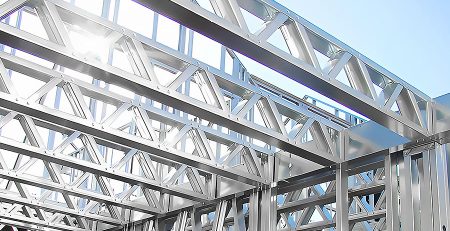

Enter modular construction and cold formed steel (CFS). Together, they form a future-proof combination that brings together speed, precision, durability, and sustainability. With the rise of smart cities and green infrastructure, the synergy between modular construction and steel framing has never been more relevant.

From advanced steel framing machines to off-site production efficiencies, this integrated system is transforming how we build. In this blog, we’ll explore why modular steel construction using cold formed steel is the definitive answer to future-proof building.

CFS – LGSF Future-Proof Construction

1. The Challenges Modern Construction Must Overcome

Modern construction faces mounting pressure from a variety of environmental, social, and economic forces. As the world rapidly changes, so must the way we build. Below are the top challenges that the construction industry must tackle head-on—and how modular steel construction offers a powerful response.

🌪️ Climate Change & Natural Disasters

The climate crisis has intensified natural disasters across the globe. From hurricanes and earthquakes to floods and wildfires, buildings are now required to withstand extreme and unpredictable conditions. Traditional timber framing often proves inadequate in these scenarios due to its susceptibility to rot, pests, fire, and structural failure under stress.

Cold formed steel framing, on the other hand, provides a robust solution. Its high strength-to-weight ratio, resistance to corrosion, and non-combustible nature make it ideal for disaster-resilient steel construction. Unlike wood, it does not warp, crack, or degrade over time, ensuring long-term performance in even the harshest environments. For architects and builders focused on resiliency, steel framing isn’t a luxury—it’s a necessity.

🏙️ Urban Density & Population Growth

With urban centers becoming increasingly crowded and vertical, the demand for smarter, more space-efficient buildings has exploded. As more people migrate to cities, the construction sector must build faster and higher—without compromising on safety or design flexibility.

Modular steel framing meets this challenge head-on. It enables rapid construction of multi-story buildings with structural components prefabricated off-site using precise steel framing machines. This approach minimizes disruption in densely populated areas, accelerates the build timeline, and allows for greater architectural creativity in constrained urban spaces. Moreover, the light weight of cold formed steel reduces foundation loads, making it easier to build upwards safely.

👷 Skilled Labor Shortages

The global construction workforce is shrinking, especially among skilled trades. Retirements, lack of vocational training, and pandemic-related disruptions have all contributed to a labor shortfall that threatens project timelines and quality standards.

To counter this, many firms are turning to automation—and steel framing machines are leading the charge. These machines transform digital blueprints into perfectly cut and punched steel profiles, eliminating the need for manual measuring and cutting. By reducing human error and manual workload, they not only boost productivity but also allow a smaller workforce to deliver large-scale steel construction projects with consistent quality and speed.

💰 Rising Material Costs

Material prices—especially for timber—have surged unpredictably in recent years. This volatility strains budgets and adds risk to long-term planning. However, cold formed steel offers a more stable, cost-effective alternative.

Thanks to the precision of steel framing machines, material waste is drastically reduced. Every profile is cut to exact specifications, minimizing scrap and maximizing efficiency. While the upfront investment in a steel framing system might be higher, the long-term return in terms of reduced waste, faster build times, and lower labor costs far outweighs the initial expenditure. In a world where margins are tight and sustainability is non-negotiable, steel construction delivers on both fronts.

2. Cold Formed Steel: The Backbone of Future-Proof Construction

Cold formed steel (CFS)—also known as light gauge steel—is rapidly becoming the backbone of modern construction systems. Unlike hot-rolled steel, CFS is shaped at room temperature, which not only conserves energy during production but also allows for tighter tolerances and lighter-weight components. Though it weighs significantly less than hot-rolled steel, it still maintains exceptional strength, stiffness, and structural reliability. This unique balance of lightness and durability is exactly what modern construction demands.

🎯 Precision Manufacturing

One of the defining advantages of cold formed steel is its precision. Using computer-controlled steel framing machines, profiles are formed with millimeter-level accuracy. This is especially vital in today’s era of digital construction, where projects often begin with Building Information Modeling (BIM) and are executed with CNC-grade precision.

Such tight tolerances mean that every component—whether it’s a stud, track, joist, or truss—fits perfectly with the next. This reduces the need for on-site adjustments and drastically shortens installation time, especially in modular steel construction where every minute counts.

🛡️ Durability That Lasts

CFS stands out for its resistance to the elements. It is non-combustible, immune to termites and rodents, and doesn’t rot or warp in high-moisture environments. Whether you’re building in tropical humidity, desert heat, or earthquake zones, cold formed steel ensures long-lasting performance.

These properties make it the ideal material for disaster-prone or high-risk regions where structural integrity is critical. When combined with steel framing machines, builders can produce durable, uniform components that meet strict safety and performance standards without sacrificing efficiency.

♻️ Sustainability in Action

Environmental concerns are now front and center in construction planning. Cold formed steel meets the moment—it is 100% recyclable, generating minimal waste during the production process. Moreover, the use of steel framing systems leads to precise material usage, eliminating overcutting and reducing scrap. This is a significant improvement over timber framing, which not only wastes more material but also contributes to deforestation.

In addition, steel construction using CFS is ideal for green building certifications such as LEED and BREEAM, helping developers meet regulatory requirements and sustainability targets.

🧱 Consistency and Reliability

Unlike timber, which can contain knots, inconsistencies, and warping, every piece of cold formed steel is identical. This uniformity ensures structural predictability and consistent performance across an entire building.

For large-scale modular construction projects—where hundreds or even thousands of identical panels must be produced—this is a game-changer. Paired with automated steel framing machines, the production process becomes streamlined, predictable, and infinitely scalable.

🔧 Seamless Integration with Steel Framing Machines

The true power of cold formed steel is unlocked when combined with the right technology. Steel framing machines turn flat steel coils into fully processed profiles—cut, punched, dimpled, and labeled—ready for immediate assembly.

This seamless integration enables rapid off-site fabrication of wall panels, floor joists, ceiling systems, and roof trusses. Once transported to the construction site, these components can be assembled in record time with minimal manpower. It’s the foundation of fast, smart, and sustainable steel construction—and the future is already here.

3. The Power of Modular Construction

Modular construction is rapidly redefining how we think about building. Instead of constructing everything on-site—where weather, labor delays, and logistical issues can wreak havoc—modular construction takes a smarter approach. Building components, or “modules,” are fabricated in off-site factories under highly controlled conditions. These modules are then transported to the job site and assembled like building blocks into a complete structure.

When paired with steel framing, modular construction becomes an even more powerful force. The precision, lightness, and strength of cold formed steel perfectly align with the modular mindset, allowing builders to scale quickly, reduce human error, and maintain consistent quality. More importantly, the use of steel framing machines in the production of these modules enables high-speed, high-volume output without sacrificing accuracy.

🚀 Speed: Accelerated Project Timelines

Modular steel construction can reduce total build time by 30% to 50% compared to traditional construction. While foundations are being laid on-site, steel framing machines are already busy producing panels, trusses, and joists off-site. This parallel workflow compresses the schedule dramatically, making it ideal for emergency housing, commercial developments, and time-sensitive infrastructure projects.

🧪 Quality: Precision-Controlled Manufacturing

By moving much of the construction process into a factory setting, quality control improves significantly. Temperature, humidity, and material handling are tightly managed—eliminating the variability that plagues open-air job sites. Thanks to the precision of steel framing machines, every component is cut, punched, and labeled with pinpoint accuracy, ensuring perfect fit and finish on-site.

🛡️ Safety: Reduced Site Risks

Construction sites are inherently risky environments, with heavy equipment, unstable structures, and ongoing human activity. Modular construction significantly reduces the amount of on-site work required. Fewer people on site means fewer accidents. Plus, pre-assembled steel frame panels are quicker and easier to install, minimizing dangerous lifting and cutting tasks.

🧩 Flexibility: Adaptable and Customizable

Modular buildings aren’t limited to repetitive boxy shapes. Thanks to the design flexibility of cold formed steel, modules can be customized for virtually any architectural style or function—residential, commercial, industrial, or institutional. Need to expand a structure in the future? No problem. With modular steel framing, buildings can be disassembled, moved, or extended with minimal disruption.

🌍 Sustainability: Low Waste, High Efficiency

Modular construction aligns perfectly with green building principles. Factory production of modules leads to tightly controlled inventory, optimized material usage, and minimal scrap. Combined with the recyclable nature of steel construction, this drastically reduces landfill waste. Additionally, because steel framing machines produce exactly what is needed—no more, no less—there’s little excess material to dispose of. Transportation-related emissions are also reduced due to fewer site deliveries and shorter build times.

🏘️ Unlimited Applications: From Tiny Homes to Skyscrapers

The versatility of modular steel construction is unmatched. It is currently being used in:\n- Emergency shelters for disaster relief\n- Affordable housing developments\n- Luxury tiny home communities\n- Pop-up healthcare and education units\n- Multi-story apartment blocks and office towers

No matter the project size or scope, combining modular methods with steel framing offers scalability, strength, and sustainability. It’s not just a new way to build—it’s a better way.

4. Why Steel Framing and Modular Construction are the Perfect Match

When you combine cold formed steel with modular steel construction methods, you create a building system that is stronger, faster, and smarter than anything traditional construction can offer. Each element enhances the other, forming a synergy that’s hard to beat in terms of speed, efficiency, and long-term flexibility.

Lightweight yet Strong: Cold formed steel has an impressive strength-to-weight ratio, making it ideal for modular units. Lighter materials mean easier transportation, quicker installation, and reduced stress on foundations—all without compromising structural integrity.

Factory-Driven Accuracy: In modular steel construction, precision matters. Cold formed steel profiles—manufactured using advanced steel framing machines—offer consistent measurements and clean finishes. This factory-level accuracy reduces human error, minimizes rework, and guarantees that every module fits as designed.

Seamless Digital Integration: Modern construction relies on digital planning tools like BIM and CAD. Cold formed steel framing integrates effortlessly with these platforms, enabling accurate design, real-time changes, and optimized material use.

Expandable and Reconfigurable: One of the greatest strengths of modular steel construction is adaptability. Need to relocate or expand a structure? No problem. Buildings constructed with steel framing can be disassembled, moved, or extended with minimal effort and cost.

This combination ensures that your projects are not only faster and safer to build, but also built to evolve—perfectly aligned with the demands of a dynamic world.

5. Steel Framing Machines: The Core of Scalable Steel Construction

Modern steel framing machines have completely transformed the way cold formed steel is processed and integrated into construction workflows. These high-precision machines serve as the backbone of scalable steel construction, enabling mass production of framing components that are accurate, consistent, and ready for immediate use.

By reading digital design files—often from BIM or CAD platforms—these machines can automatically punch, cut, and shape profiles with minimal human intervention. Whether you’re producing simple wall studs or complex trusses, the process is seamless and lightning-fast.

🔄 Key Advantages of Steel Framing Machines

🔧 Automation:

By automating key steps such as measuring, punching, cutting, and labeling, steel framing machines drastically reduce the need for manual labor. This is especially valuable in regions where skilled labor is scarce or expensive.🚀 Speed:

These machines are built for volume. A single steel framing machine can process hundreds of meters of framing per hour, making it possible to meet tight deadlines in fast-paced modular steel construction projects.🛠️ Customization:

Web width, flange height, punching patterns—nearly every profile detail can be customized. This flexibility is essential for adapting to different building types, from residential housing to industrial structures.🎯 Accuracy:

Precision is everything in steel framing. When components fit perfectly, on-site assembly becomes faster, easier, and more reliable. Less error also means less waste and fewer costly corrections.

🏭 Real-World Example: UNBAK ICARUS Machines

UNBAK’s ICARUS series of steel framing machines exemplifies the cutting edge of this technology. Models like the IC-2500SA and IC-5500SA support multiple web widths, allowing builders to switch between framing sizes with minimal downtime. Semi-automatic and fully automatic changeovers give teams flexibility depending on production volume and job type.

These machines integrate smoothly with digital design platforms, making it easy to go from 2D or 3D design to production in minutes. Whether you’re building modular homes, schools, healthcare units, or large-scale residential buildings, ICARUS machines give you the speed, precision, and scalability needed to stay ahead in modern steel construction.

6. Real-World Applications and Case Studies

The power of modular cold formed steel construction isn’t just theoretical—it’s being proven every day across the globe. From rapid disaster response to long-term infrastructure, builders are using the unique strengths of steel framing and steel framing machines to solve urgent, real-world problems with speed, precision, and durability.

🆘 Disaster Relief Housing

In the aftermath of earthquakes, floods, or other natural disasters, time becomes a life-saving factor. Delays in building emergency shelters can mean the difference between survival and crisis. Modular steel construction allows for pre-fabricated units to be manufactured off-site, shipped in compact form, and rapidly assembled on-site in just a few days.

Cold formed steel ensures that these structures remain resilient in the face of further environmental stress—offering safety, insulation, and durability even in extreme conditions. Combined with automated steel framing machines, these modules can be produced at scale, ready for deployment at a moment’s notice.

🏠 Tiny Homes & Affordable Housing

As the global housing crisis deepens, governments and non-profit organizations are turning to modular steel framing to build cost-effective, energy-efficient homes at scale. Tiny house projects, in particular, benefit from the lightweight and space-efficient nature of cold formed steel framing.

Thanks to precision production through steel framing machines, housing units can be standardized and assembled with minimal time and manpower—making it possible to deliver entire communities in a fraction of traditional construction timelines.

🏢 Commercial Buildings

Whether it’s office complexes, schools, retail centers, or mobile clinics, modular steel construction is reshaping the commercial sector. Developers and municipalities are choosing cold formed steel not just for speed, but for long-term value.

Projects that once took many months to complete can now be delivered in weeks—without compromising architectural quality or structural performance. Every wall panel, joist, and frame can be produced by steel framing machines to exact specifications, reducing waste, simplifying logistics, and ensuring flawless execution on-site.

Each of these applications clearly shows how combining modular design with cold formed steel and automated steel framing technology isn’t just innovative—it’s essential. In today’s fast-moving, resource-constrained world, it’s the only way to meet the growing demand for fast, flexible, and resilient construction.

7 Critical Mistakes in Light Steel Frame Construction – And How to Avoid Them

Step-by-Step Guide to the Construction of Light Steel Frame Structures: Click

Sound and Thermal Insulation in Light Steel Frame Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply