The global housing crisis is no longer a distant concern—it has evolved into a pressing and widespread issue affecting communities across continents. From high-density urban zones in North America to rapidly expanding rural populations in Asia and Africa, access to affordable, safe, and quickly delivered housing is becoming more difficult with each passing year. Traditional construction methods such as concrete and timber are increasingly unable to meet the growing demand due to long lead times, high costs, and limited scalability.

To overcome these limitations, the industry is shifting toward more advanced and efficient systems—led by innovations in steel construction technology. Among these, Light Gauge Steel Framing (LGSF) has emerged as a transformative approach, offering a combination of speed, structural reliability, and sustainability. Leveraging precision-driven cold formed steel components and automated fabrication processes, LGSF is proving to be a game-changer in how affordable housing is designed, built, and delivered.

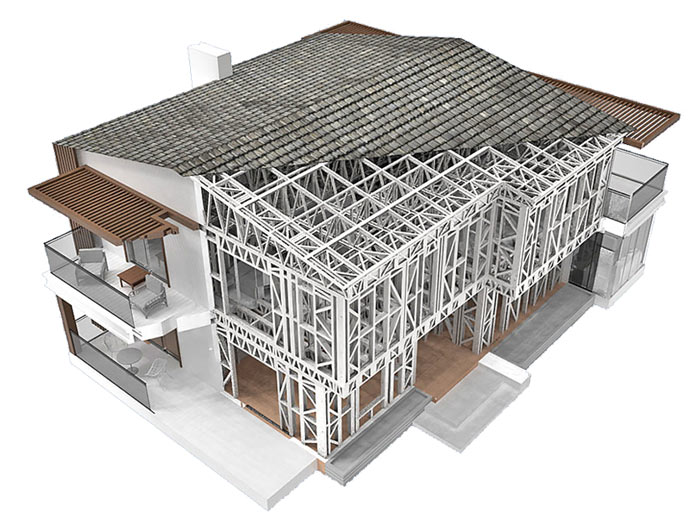

At the heart of this revolution is light steel framing, a system based on high-strength, lightweight steel profiles that are produced with remarkable consistency using advanced rollform machines. These steel framing machines translate digital building models into physical steel frames with near-zero error, ensuring that production and installation are faster, cleaner, and more cost-efficient than ever before.

Thanks to its integration with BIM workflows and its compatibility with modular and prefabricated building systems, steel framing not only shortens project timelines but also enhances quality control across every stage of construction. Whether deployed in emergency shelter programs, social housing developments, or urban infill projects, LGSF delivers scalable, flexible solutions that directly address the challenges of modern housing shortages.

This guide will explore why cold formed steel and light gauge steel framing are rapidly becoming the global standard for affordable housing construction. We’ll examine the role of steel framing machines, highlight the benefits of rollform automation, and show how this innovative method is reshaping the future of residential construction around the world.

1. The Global Demand for Affordable Housing

Across the globe, housing affordability has reached critical levels. A growing population, urbanization, and economic disparity have intensified the pressure on governments and developers to find scalable housing solutions. According to a UN-Habitat report, more than 1.6 billion people are currently living in inadequate housing, with an estimated 100 million individuals completely homeless. This crisis affects not only low-income regions but also middle-income countries, where rising material costs and land shortages have pushed even basic housing out of reach.

In response, governments, NGOs, and private developers are under mounting pressure to deploy housing strategies that are not only cost-effective, but also fast, flexible, and environmentally responsible. The traditional construction ecosystem—largely built on timber framing and reinforced concrete—has proven too slow, labor-intensive, and costly to meet today’s accelerated housing needs. Long construction times, skilled labor shortages, supply chain disruptions, and environmental degradation have further revealed the limitations of outdated building systems.

This is where Light Gauge Steel Framing (LGSF) stands out as a disruptive force. Leveraging modern steel construction technology, LGSF provides a repeatable and modular approach to mass housing that reduces on-site labor and material waste. Unlike conventional methods that can take over a year or more to complete, LGSF-based light steel framing systems enable entire housing units to be produced off-site, transported in panels, and installed in a matter of weeks—often 50% to 70% faster than traditional builds.

Moreover, the use of cold formed steel profiles—manufactured via advanced rollform machinery—ensures unmatched precision, strength, and consistency. These framing elements can be fabricated using a steel framing machine directly from BIM or CAD designs, drastically reducing the risk of human error and rework. This digital-to-physical integration allows for faster approvals, predictable outcomes, and lower costs per square meter—all of which are crucial in affordable housing developments.

In densely populated cities and remote rural areas alike, steel framing offers a high-performance solution that is scalable, lightweight, and easy to transport. It’s especially valuable for governments managing emergency housing programs or resettlement projects where time and reliability are paramount.

The global demand for resilient, fast-to-build homes makes it clear: light gauge steel construction is not a luxury—it’s a necessity. And with rising awareness of its benefits, LGSF is quickly becoming the preferred system for building affordable, sustainable housing at scale.

2. What is Light Gauge Steel Framing?

Light Gauge Steel Framing (LGSF) is a modern construction system that utilizes thin, galvanized cold formed steel profiles to build the structural skeleton of buildings, including walls, floors, and roofs. These profiles are manufactured through a highly accurate process using advanced rollform technology, enabling high-volume production with remarkable consistency, minimal material waste, and exceptional structural integrity.

At the heart of the LGSF method is its reliance on steel framing machines—sophisticated, CNC-controlled systems capable of producing custom steel profiles directly from BIM or CAD design files. This level of automation and precision eliminates many of the inaccuracies and delays commonly found in traditional construction methods, especially when working with timber or masonry.

Light steel framing offers a superior alternative to conventional systems by providing high strength-to-weight ratios while remaining lightweight and easy to transport. The frames maintain dimensional accuracy even over long spans, ensuring that structures remain straight, stable, and easy to assemble. This is especially critical in affordable housing developments, where rapid deployment and low construction costs are essential.

Key Features of LGSF Include:

- Lightweight yet strong steel structures that reduce foundation loads

- High precision thanks to cold formed steel processing with automated rollform systems

- Fast installation and disassembly, ideal for temporary housing or scalable modular units

- Flexible design capabilities that allow architects to develop various housing typologies—without driving up costs

In affordable housing projects, the off-site manufacturing capabilities of LGSF dramatically accelerate construction schedules. Entire wall and roof panels can be pre-engineered in a controlled environment using steel framing machines, then delivered to the jobsite for rapid installation. This reduces on-site labor dependency and minimizes exposure to weather-related delays.

By combining the benefits of light steel framing with cutting-edge steel construction technology, LGSF empowers developers and governments to deliver reliable, sustainable, and repeatable housing at scale.

3. Why Light Gauge Steel is Perfect for Affordable Housing

3.1 Cost Savings

One of the most compelling reasons to choose light steel framing for affordable housing is the dramatic reduction in material and labor costs. Using precision-engineered cold formed steel profiles manufactured via rollform machines, the production process generates minimal waste compared to timber or concrete. Every steel coil is utilized efficiently, lowering raw material expenses across the board.

Transportation costs are also significantly reduced. Steel framing components are lightweight and compact, allowing more materials to be shipped per load and cutting down on fuel and logistics overhead. On the jobsite, the streamlined installation process requires smaller crews and less specialized labor, resulting in substantial savings on wages and construction management.

With lower input costs, housing providers can offer high-quality units at prices that are accessible to a broader population—without compromising on safety or design.

3.2 Speed of Construction

Affordable housing solutions must be fast—not just economical. LGSF systems excel here too. Using advanced steel framing machines, wall panels, roof trusses, floor joists, and framing modules are fabricated in off-site facilities and shipped to site ready for rapid assembly.

Thanks to the high precision of rollformed cold formed steel, components fit together perfectly, eliminating time-consuming rework and delays. This level of efficiency allows builders to cut construction timelines by 30% to 60% compared to conventional methods. In some cases, entire multi-unit housing complexes can be completed in just a few months.

The accelerated build cycle reduces financing overheads, shortens the return on investment period, and allows communities in crisis to receive housing in record time.

3.3 Strength and Durability

Beyond cost and speed, LGSF structures deliver impressive longevity and resilience. Light steel framing is naturally resistant to termites, mold, rot, and fire—problems that plague wood-framed homes, especially in humid or disaster-prone regions.

Cold formed steel does not warp, split, or degrade over time, even in extreme temperatures or high-humidity zones. This makes it an ideal choice for affordable housing that must remain safe and habitable for decades with minimal maintenance.

In hurricane zones, seismic regions, or flood-prone areas, LGSF has been proven to outperform traditional materials in structural performance. For governments and developers focused on long-term housing value, this durability translates into lower lifecycle costs and fewer repairs over time.

3.4 Design Flexibility

Contrary to the myth that affordable housing must be bland or uniform, LGSF offers remarkable design versatility. Cold formed steel profiles can be customized in width, shape, and punching patterns using modular settings on the steel framing machine—allowing for architectural freedom without complexity.

Whether the goal is to replicate local building traditions or adapt homes to specific cultural and climatic contexts, light steel framing allows architects to do so without escalating costs. Curved walls, split levels, and variable roof pitches are all achievable within LGSF systems—something rarely possible in prefabricated housing made from concrete or block.

This design freedom empowers housing providers to deliver not only affordable, but also dignified, comfortable, and locally appropriate homes—bridging the gap between efficiency and livability.

4. How Steel Framing Machines Support Mass Housing Projects

To meet the urgent demand for affordable housing at a global scale, manufacturers need more than just efficient designs—they need high-speed, reliable, and scalable production systems. This is where advanced steel framing machines come into play. Technologies such as rollformers, automated punch units, and CNC-controlled framing systems are transforming the way cold formed steel components are produced and assembled.

These machines are the backbone of any modern LGSF (Light Gauge Steel Framing) production line. With the ability to convert digital building models into physical framing components with millimeter precision, they eliminate the delays and errors commonly associated with manual cutting, measuring, and punching.

Key Advantages of Steel Framing Machines for Affordable Housing:

Automated Production Minimizes Human Error: Once a design file is loaded into the system, the steel framing machine handles the entire forming, cutting, and punching sequence automatically. This ensures each component is consistent and reduces reliance on skilled labor—ideal for fast-paced modular housing projects.

Multi-Profile Programming for Diverse Housing Models: Modern rollform machines can be configured to handle multiple base sizes and punching sets. This flexibility means a single line can produce frames for various unit types—from single-story homes to multi-family apartments—without retooling the entire system.

Seamless BIM Integration: With compatibility for BIM (Building Information Modeling) and CAD software, these machines can pull architectural and structural data directly from the digital model. This creates a closed-loop workflow where designs are fabricated without intermediate file conversions, reducing time and error in the design-to-production pipeline.

Scalability with LGSFLEX: Systems like UNBAK’s LGSFLEX platform offer expandable hardware and software features, allowing manufacturers to gradually enhance their production capabilities. Instead of investing in a completely new machine, users can integrate additional punch modules, web width settings, or profile libraries, making the system ideal for long-term growth in the affordable housing sector.

By prefabricating wall panels, roof trusses, and floor joists with cold formed steel, builders achieve industrial-level efficiency while maintaining high structural standards. This combination of speed, precision, and modularity is essential to building thousands of homes—on time and within budget.

5. Sustainability Benefits of Light Gauge Steel Structures

In today’s construction landscape, sustainability is no longer optional—it is a fundamental requirement. As governments and developers face growing pressure to meet climate goals and reduce environmental impact, Light Gauge Steel Framing (LGSF) emerges as a frontrunner in sustainable building technology. When paired with smart design and responsible sourcing, light steel framing systems provide a green, scalable solution to the global affordable housing crisis.

Environmental Advantages of LGSF:

Recyclable Materials: Steel is one of the most sustainable construction materials available. Unlike timber or concrete, cold formed steel is 100% recyclable and can be reused indefinitely without any degradation in quality or strength. This circular material life cycle significantly reduces the demand for raw resource extraction and landfill contribution.

Reduced Waste Through Precision Manufacturing: Steel framing machines equipped with automated rollform technology minimize waste by producing framing elements to exact specifications. Because every cut, notch, and punch is digitally pre-planned, offcuts and scrap are kept to an absolute minimum—a major improvement over traditional construction where material wastage is common and costly.

Improved Energy Efficiency: LGSF structures support high-performance insulation systems and minimize thermal bridging, which can otherwise lead to energy loss in traditional buildings. By incorporating proper insulation details and airtight design, light steel framing can meet and exceed many green building certification standards, including LEED, BREEAM, and EDGE.

Low Impact Modular Construction: Many LGSF projects utilize off-site modular construction, further enhancing sustainability. This method significantly reduces on-site disruption, lowers noise and dust pollution, and shortens the construction timeline—all of which contribute to a lower carbon footprint per unit built.

6. Case Studies and Real-World Examples

6.1 Modular Housing for Homeless Programs

In several U.S. states such as California, Texas, and Washington, local governments have turned to LGSF-based modular housing units to rapidly respond to rising homelessness. By utilizing cold formed steel panels manufactured off-site using advanced rollform machines, entire communities of transitional housing can be installed within just a few months—often at a fraction of the cost of traditional construction.

These light steel structures are not only fast to deploy but also durable, easily transportable, and highly configurable. Using steel framing machines, each module can be customized to meet local zoning requirements while maintaining consistent quality and safety standards.

By reducing construction time and streamlining permitting and logistics, modular steel framing systems have helped municipalities reduce administrative burdens and provide dignified, long-lasting shelter to those in need.

6.2 Emergency Housing Post-Natural Disasters

In disaster-prone regions—including Southeast Asia, the Caribbean, and parts of South America—LGSF modular housing systems have played a vital role in rapid disaster recovery. Whether responding to hurricanes, floods, or earthquakes, governments and aid agencies have leveraged the strength and lightweight properties of cold formed steel to erect emergency housing in record time.

Because light steel framing does not warp, rot, or degrade under extreme environmental conditions, it offers a safe and reliable alternative to tents or temporary wooden shelters. Rollformed steel panels can be pre-punched and pre-cut using steel framing machines, then flat-packed for easy transport and assembled on-site with minimal labor.

The modularity of LGSF systems also enables phased expansion—allowing housing to evolve from temporary shelter into semi-permanent or permanent residences without major design changes. This scalability is invaluable in disaster recovery scenarios, where rebuilding needs are urgent but often unpredictable.

6.3 Urban Affordable Housing Projects

Major metropolitan areas around the world—including London, Melbourne, Los Angeles, Toronto, and Dubai—are facing rising demand for affordable housing amid escalating land prices and infrastructure constraints. Light Gauge Steel Framing offers a solution by enabling high-density modular apartment construction with reduced build times and minimal site disruption.

By using cold formed steel framing systems, architects can design multi-story buildings that comply with strict fire, seismic, and energy codes while maintaining construction efficiency. Steel framing machines make it possible to create intricate panel layouts, multiple web width options, and integrated service holes that support faster plumbing and electrical installation.

For developers, LGSF modular housing minimizes labor costs and financing risks. For cities, it accelerates the delivery of much-needed housing without overburdening public infrastructure. And for residents, it delivers safe, modern, and customizable living spaces—often in half the time of a concrete build.

7. The Future Outlook: Steel Framing and the Evolution of Housing

As governments and developers face mounting pressure to address the global housing crisis, light gauge steel framing will become an even more integral part of the solution.

Key Trends:

- Modular & Off-Site Construction on the Rise

Prefabricated buildings constructed with cold formed steel profiles allow for mass housing development without the delays and unpredictability of on-site labor. The global shift toward modular construction is expected to accelerate the adoption of LGSF in both residential and non-residential sectors. - Automation and Smart Rollform Machines

As automation advances, steel framing machines are becoming faster, more intelligent, and increasingly integrated with BIM platforms. This trend will make high-volume production of steel framing components more accessible and scalable for small- to mid-size manufacturers—further democratizing housing production. - Green Building and Sustainability Standards

With governments enforcing stricter green building codes, LGSF systems—made from 100% recyclable steel—are naturally aligned with ESG (Environmental, Social, and Governance) goals. Superior thermal performance, reduced construction waste, and long-lasting durability make light steel framing a top choice for eco-conscious developers. - Expansion into Commercial and Public Infrastructure

The use of light gauge steel framing is no longer limited to homes. Hospitals, schools, office buildings, and even retail centers are now being constructed using cold formed steel framing, thanks to its adaptability, speed, and structural integrity.

Affordable housing is no longer a distant dream—it’s an urgent global necessity. In the face of rapid urbanization, rising material costs, and increasing social demand, the construction industry must adopt faster, smarter, and more scalable building solutions.

Light Gauge Steel Framing (LGSF), powered by cold formed steel rollforming technology, delivers the speed, efficiency, and sustainability required to tackle this challenge. With high-precision production enabled by steel framing machines, and the flexibility of modular construction, LGSF is setting a new standard for building safe, cost-effective homes at scale.

For developers, governments, and construction firms, the path forward is clear: investing in advanced rollform systems, integrating digital design-to-fabrication workflows, and adopting light steel framing as the backbone of modern housing solutions.

Handbook for Light Gauge Steel Structure Production – How LGS Done?

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply