THE FUTURE IS IN LIGHT STEEL STRUCTURES

Be a Part of the Growing Light Steel Structure Market Worldwide

Why Light Steel Structure? The global market projection for light steel structures has shown continuous growth in recent years. This increase is supported by advantages such as the rapid construction process, high durability, and environmental sustainability that light steel offers. Especially in developing cities and rapidly growing construction sectors, the use of light steel in building projects is increasing. Additionally, the recognition of light steel as an energy-efficient and recyclable material contributes to its larger market share globally. This trend is expected to continue in the coming years.

GLOBAL LIGHT STEEL STRUCTURE MARKET

The Light Steel Structure Market is Growing

The rapid growth of the light steel structure market worldwide signifies an important trend for the modern construction industry. Light steel is increasingly preferred due to its advantages such as a rapid construction process, high durability, and environmental sustainability. Developing cities and rising construction demands are boosting the use of light steel, while its energy efficiency and recyclability are contributing to the market’s expansion.

ADVANTAGES OF LIGHT STEEL STRUCTURES

Be a Part of the Growing Global Light Steel Structure Market

Light steel typically refers to cold-formed steel products used in structural, non-structural, and finishing applications in construction. The reasons for choosing light steel over other construction materials are numerous, making it suitable for a variety of applications.

Strength-to-Weight Ratio: Light steel offers an impressive strength-to-weight ratio, making it a robust yet lightweight material suitable for various structural applications.

Durability: Steel is resistant to many common issues that affect other building materials. It does not rot, warp, or get infested by pests like termites. With proper protective coatings, it can also resist rust and corrosion.

Construction Speed: Light steel components can be pre-manufactured off-site, allowing for quick assembly on-site. This not only accelerates project completion but also ensures precision and reduces labor costs.

Design Flexibility: The malleability of steel allows for a wide range of architectural designs. Whether it involves intricate detailing or large open spaces, light steel can accommodate various architectural visions.

Sustainability: Steel is 100% recyclable, making it an environmentally friendly choice. When a building is demolished, steel components can be reused or recycled, reducing environmental impact.

Consistency and Predictability: Steel production is highly controlled, ensuring that the structural properties of light steel are consistent. This predictability is critical for the safety and reliability of steel structures.

Fire Resistance: Steel is non-combustible, making structures more resistant to fire. When combined with fire-resistant materials, light steel structures can achieve significant fire resistance ratings.

Seismic Performance: Light steel structures have demonstrated excellent performance during seismic events. Their flexibility and strength make them resilient to earthquakes, especially when designed with seismic considerations.

Thermal Efficiency: When combined with proper insulation, light steel framing can provide excellent thermal performance, leading to energy savings.

Cost Efficiency: The speed of construction, reduced labor costs, and minimal waste associated with light steel can lead to cost savings. Additionally, its durability reduces maintenance costs over the lifespan of the structure.

Dimensional Stability: Steel does not expand or contract with changes in moisture content, ensuring that the structure remains stable over time.

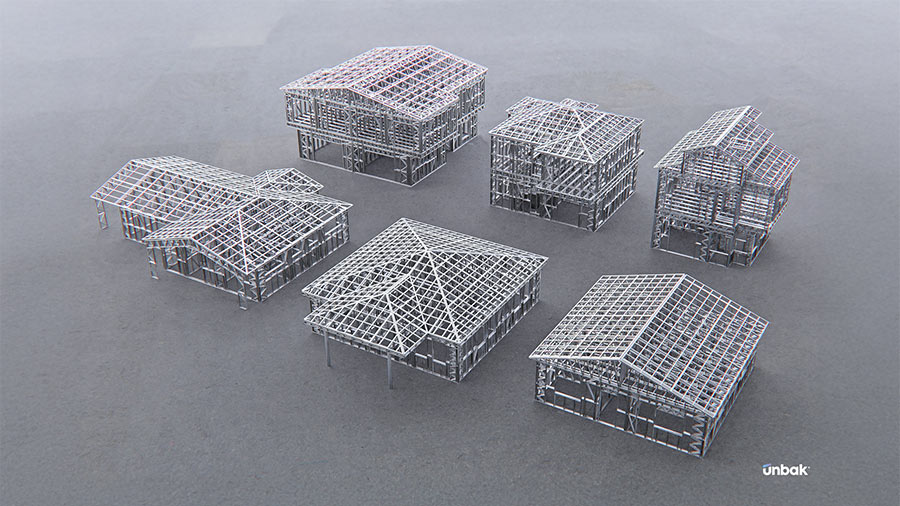

FLEXIBLE CONSTRUCTION VARIATIONS

Flexible, Easy and Fast Light Steel Constructions

WIDE PRODUCT RANGE

Eye-Catching Design

UNBAK Light Steel Structure Machines are built on details that prioritize design alongside functionality. Our machine portfolio includes light steel structure machines suitable for the needs of every light steel structure project.

MACHINE DESIGN DETAILS

Striking Design

UNBAK LSF Light Steel Frame Machines family built with attention to both functionality and design details. From the machine user interface to the exterior details, all ICARUS LSF machines stand out with their ease of use and distinctive designs.

UNBAK machines are crafted with careful attention to both external and internal design details. Features like easy equipment changes and the simplicity of roller and mold adjustments have been designed and delivered to you based on 33 years of experience in roll forming machinery.

COMPANIES WORKING WITH US

OUR SOLUTION PARTNERS

IC - 1000SA

The 1000SA is the entry-level light steel structure machine of the UNBAKS LSF machinery family that can produce multiple base sizes.

This compact light steel structure machine can work with a maximum sheet thickness of 1.2mm and can produce three base sizes. It is capable of manufacturing Roof Trusses, Wall Panels, and Truss

IC - 2500SA

IC-2500SA is the mid-professional level light steel structure machine of the UNBAKS LSF machinery family that can produce a single web size.

This light steel structure machine can work with a maximum sheet thickness of 1.6mm and can produce Multiple web sizes. It is capable of manufacturing Roof Trusses, Wall Panels, and Truss.

IC - 3000SERIES

The 3000 Series is the professional level light steel structure machine of the UNBAKS LSF machinery family that can produce multiple web - flange sizes.

3000Series can work with a maximum sheet thickness of 2.5mm and can produce multiple web - flange sizes. It can produce Roof Trusses, Wall Panels, Lattice Joist and Floor Joists

IC - 5000SERIES

The 5000 Series is the professional level light steel structure machine of the UNBAKS LSF machinery family that can produce multiple web - flange sizes.

5000Series can work with a maximum sheet thickness of 2.5mm and can produce multiple web - flange sizes. It can produce Roof Trusses, Wall Panels, Lattice Joist and Floor Joists

News from UNBAK

How Steel Framing Rollform Machines Enable Unmatched Flexibility

Basics of Wall Cladding Assembly in LGSF

Light Steel Framing Machine Factory Needs and Setup

Design Flexibility Fast Production in Steel Frame Machine - Construction

Frequently Asked Questions

What are the most common issues customers experience after purchasing the product?

ICARUS2024-07-29T11:15:18+00:00Our machine is user-friendly, but an operator without sufficient experience or training may find it difficult to set up the machine properly. Therefore, the initial training we provide at our facility plays a crucial role in ensuring the longevity of the machine and error-free production for the buyer's operator.What is your company’s maximum commitment time for initiating the resolution of an issue?

ICARUS2024-07-29T11:15:58+00:00When you become a part of the UNBAK Family, a WhatsApp group is created as a priority to quickly manage our after-sales services. Issues such as production errors and operator questions are addressed within the first 5-15 minutes. In the second phase, we remotely connect to the machine and inspect it through the software, fixing any issues that can be corrected immediately. In the third phase, we conduct a video call via WhatsApp for problem identification and resolution. If a spare part replacement is deemed necessary during this phase, it will be shipped from our stock to your location, no matter where you are in the world. If the problem cannot be resolved in the third phase or requires faster intervention, a visit to your workplace is planned and carried out.In an emergency, our technician team will visit your factory to resolve the issue on-site.We prefer to train your operator at our facility before the delivery of your machine. Typically, we invite the customer’s operator to our facility just before the machine's delivery.Can a specific production sequence be programmed for home assemblies (walls, beams, and trusses)?

ICARUS2024-07-29T11:16:14+00:00The sequence of operations can be arranged through VertexBD, Revit-Strucsoft, and Framebuilder MDR programs.Is there software that stops the machine when each wall/beam/truss package is completed?

ICARUS2024-07-29T11:16:29+00:00Yes, there is. The machine will stop and give a warning 10 meters before the project cycle is completed.Does your company offer or know of third parties that can take our home design and production guidelines to create the frame machine file? This is likely a service we will consider.

ICARUS2024-07-29T11:16:38+00:00Our software partners are VertexBD, Revit-Strucsoft, and Framebuilder MDR. Training on design software is provided by us to a person designated by the machine owner.

Why UNBAK

UNBAK Machinery's development process rises on rollforming machinery and software. You can find UNBAK's 33 years of rollform machinery experience and gain a clearer understanding of why customers from all over the world prefer us.

Light Steel Applications

Discover the flexibility, durability and variations of light steel structure applications and potentials achievable with UNBAK LSF steel frame machines and systems. See what you can do with our systems.

Resources

On this page, you can find details about all the machines included in the UNBAK LSF Steel Framing family, as well as comprehensive documents related to light steel structures and gauge steel connection details.

Contact US

You can reach us by phone, email, or through the live support panel on our website. For service requests, please fill out the service form, and we will contact you promptly.

Let Us Know If You Would Like a Call Back

Documentation

IC-1000SERIES Catalog

You can download the catalog related to the IC-1000 Series from here.

IC-2000SERIES Catalog

You can download the catalog related to the IC-2000 Series from here.

IC-3000SERIES Catalog

You can download the catalog related to the IC-3000 Series from here.

IC-5000SERIES Catalog

You can download the catalog related to the IC-5000 Series from here.

IC-7000SERIES Catalog

You can download the catalog related to the IC-7000 Series from here.

IC-XMOBILE Catalog

You can download the catalog related to the IC-XMOBILE Series from here.

FRAMER EXPERT Ver.4

FRAMER EXPERT Ver.4 Software Interface Details.

Machine Compare Chart

ICARUS LSF Machine compare chart. All details .