DIFFERENT and SPECIAL PUNCHES

UNBAK light steel structure machines, developed by UNBAK Machinery CO LTD as a result of 33 years of rollforming experience, offer a variety of molds for different purposes and can design molds based on your 2D drawings, helping you create the desired profiles and connections.

The different mold types available in UNBAK include Hexagonal Mold, Oval Service Hole, Multi-Dimple Mold, Corner Rectangle Mold, Flange Bolt Hole Mold, customized hole groups for different diameters, and many other special mold sets that can be offered as optional features with the machines to our customers.

CUSTOM PUNCHES, CUSTOM PROJECTS

For Custom Projects Requiring Special Molds, Choose UNBAK

Beyond standard custom molds, fully customer-designed molds with accompanying drawings are produced, tested, and delivered exclusively to our clients. New custom molds can also be ordered after acquiring UNBAK machines and can be applied to your existing machine within its operational limits.

Unlimited Variations of Punch / Mold

With 33 years of rollforming experience and deep industry expertise, UNBAK Machinery CO LTD has developed UNBAK machines as a leading solution partner in the light steel structure sector. Produced with high engineering standards, UNBAK light steel structure machines offer versatile mold options for various construction projects. Our company is recognized for its expertise in delivering innovative solutions tailored to the specific needs of our customers.

UNBAK machines are not limited to standard molds; they also provide exceptional flexibility in producing custom molds that bring our clients’ unique designs and 2D drawings to life. These molds are crafted to create the desired profiles and connections with the highest precision.

CUSTOM PUNCH PRODUCTION SCHEME

Roadmap for Producing Custom Molds

Custom molds are produced with UNBAK light steel structure machines or by adhering to the limits of your existing UNBAK machines. The custom mold is meticulously crafted with multiple stages of inspection and low tolerances.

The procedure for producing custom molds is as follows:

– Customer Approval for Custom Mold

– Submission of 2D Drawing of the Requested Mold

– Conversion of 2D Drawing to 3D

– Conducting Stress Tests in a Virtual Environment

– Production of the Mold

– Delivery of the Mold to the Customer

FAST and EASY PUNCH CHANGE

Change Molds in Minutes with Slide&Lock System

UNBAK machines in the “SA” series come equipped with the SlideLock system. With this system, you can easily replace the mold core within minutes by simply removing a single bolt. This allows you to install a completely different mold or adjust the profile base size of your machine by changing to the appropriate mold set. The SlideLock system makes mold changes simple, fast, and requires minimal skill.

News from UNBAK

How Steel Framing Rollform Machines Enable Unmatched Flexibility

Basics of Wall Cladding Assembly in LGSF

Light Steel Framing Machine Factory Needs and Setup

Design Flexibility Fast Production in Steel Frame Machine - Construction

Frequently Asked Questions

What are the most common issues customers experience after purchasing the product?

ICARUS2024-07-29T11:15:18+00:00Our machine is user-friendly, but an operator without sufficient experience or training may find it difficult to set up the machine properly. Therefore, the initial training we provide at our facility plays a crucial role in ensuring the longevity of the machine and error-free production for the buyer's operator.What is your company’s maximum commitment time for initiating the resolution of an issue?

ICARUS2024-07-29T11:15:58+00:00When you become a part of the UNBAK Family, a WhatsApp group is created as a priority to quickly manage our after-sales services. Issues such as production errors and operator questions are addressed within the first 5-15 minutes. In the second phase, we remotely connect to the machine and inspect it through the software, fixing any issues that can be corrected immediately. In the third phase, we conduct a video call via WhatsApp for problem identification and resolution. If a spare part replacement is deemed necessary during this phase, it will be shipped from our stock to your location, no matter where you are in the world. If the problem cannot be resolved in the third phase or requires faster intervention, a visit to your workplace is planned and carried out.In an emergency, our technician team will visit your factory to resolve the issue on-site.We prefer to train your operator at our facility before the delivery of your machine. Typically, we invite the customer’s operator to our facility just before the machine's delivery.Can a specific production sequence be programmed for home assemblies (walls, beams, and trusses)?

ICARUS2024-07-29T11:16:14+00:00The sequence of operations can be arranged through VertexBD, Revit-Strucsoft, and Framebuilder MDR programs.Is there software that stops the machine when each wall/beam/truss package is completed?

ICARUS2024-07-29T11:16:29+00:00Yes, there is. The machine will stop and give a warning 10 meters before the project cycle is completed.Does your company offer or know of third parties that can take our home design and production guidelines to create the frame machine file? This is likely a service we will consider.

ICARUS2024-07-29T11:16:38+00:00Our software partners are VertexBD, Revit-Strucsoft, and Framebuilder MDR. Training on design software is provided by us to a person designated by the machine owner.

Why UNBAK

UNBAK Machinery's development process rises on rollforming machinery and software. You can find UNBAK's 33 years of rollform machinery experience and gain a clearer understanding of why customers from all over the world prefer us.

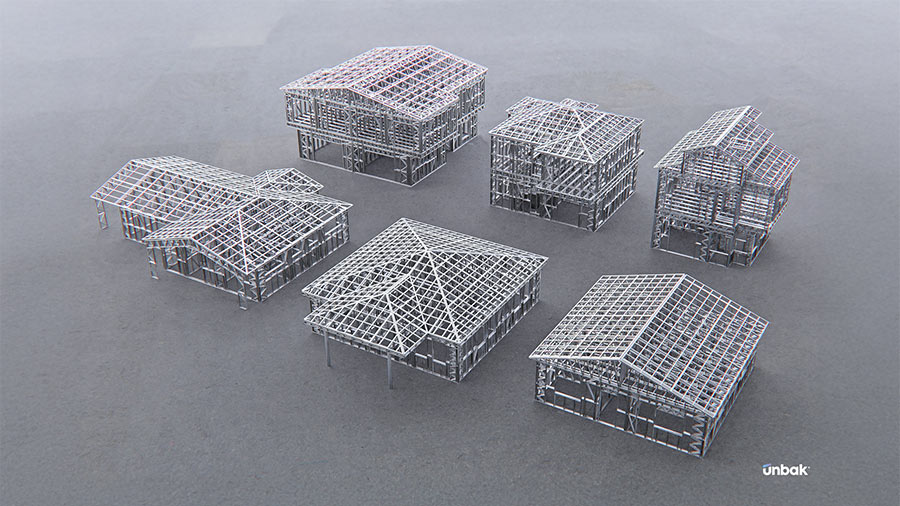

Light Steel Applications

Discover the flexibility, durability and variations of light steel structure applications and potentials achievable with UNBAK LSF steel frame machines and systems. See what you can do with our systems.

Resources

On this page, you can find details about all the machines included in the UNBAK LSF Steel Framing family, as well as comprehensive documents related to light steel structures and gauge steel connection details.

Contact US

You can reach us by phone, email, or through the live support panel on our website. For service requests, please fill out the service form, and we will contact you promptly.

Let Us Know If You Would Like a Call Back

Documentation

IC-1000SERIES Catalog

You can download the catalog related to the IC-1000 Series from here.

IC-2000SERIES Catalog

You can download the catalog related to the IC-2000 Series from here.

IC-3000SERIES Catalog

You can download the catalog related to the IC-3000 Series from here.

IC-5000SERIES Catalog

You can download the catalog related to the IC-5000 Series from here.

IC-7000SERIES Catalog

You can download the catalog related to the IC-7000 Series from here.

IC-XMOBILE Catalog

You can download the catalog related to the IC-XMOBILE Series from here.

FRAMER EXPERT Ver.4

FRAMER EXPERT Ver.4 Software Interface Details.

Machine Compare Chart

ICARUS LSF Machine compare chart. All details .