Galvanized vs. Magnelized Steel: Why Magnelized Steel is More Suitable for LGSF: Why Magnelized Steel is More Suitable for LGSF: In the construction world, materials matter greatly. Especially in light steel frame (LGS) systems, the type of steel used plays a crucial role in the durability, corrosion resistance, and overall performance of the structures. Two steel coating types frequently discussed in the industry are galvanized steel and magnelized steel. While both options have their own advantages, magnalized steel is emerging as the superior material for light steel structure projects due to its enhanced properties.

In this blog post, we will explore the main differences between galvanized and magnelized steel, and explain why magnelized steel is increasingly considered the optimal choice for light steel frame construction.

1. What is Galvanized Steel?

Galvanized steel is steel that has been coated with zinc. This coating is applied through a process called galvanization, where the steel is dipped into molten zinc, creating a zinc layer on the surface. The zinc coating protects the steel from corrosion by acting as a barrier against external elements, preventing rusting.

Key advantages of galvanized steel include:

- Corrosion resistance: The zinc layer provides good protection against corrosion, particularly in regular outdoor environments.

- Cost-effective: Galvanized steel is relatively affordable and easy to produce.

- Durability: It offers long-lasting performance and requires little maintenance over time.

However, galvanized steel does have some weaknesses. In environments with high humidity or saltwater exposure, the zinc coating can gradually wear off, leaving the steel vulnerable to rust.

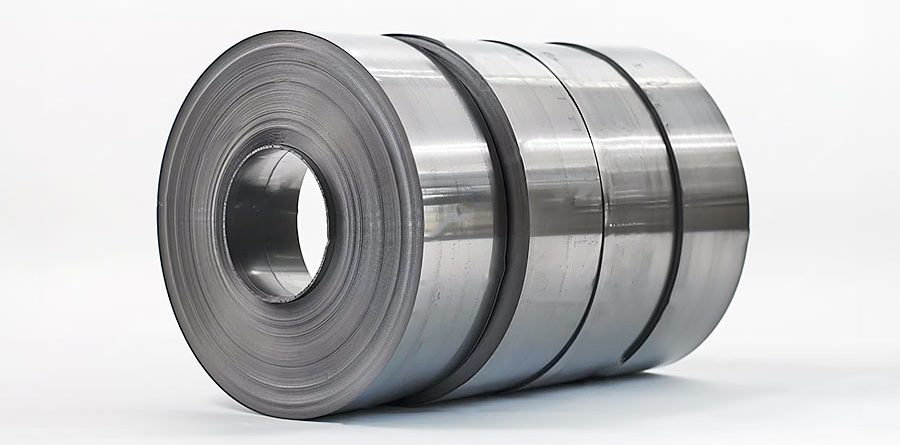

2. What is Magnelized Steel?

Magnelized steel is an advanced steel material coated with a zinc, magnesium, and aluminum alloy. This coating significantly enhances the steel’s corrosion resistance, outperforming traditional galvanized steel. The magnelized coating creates a stronger barrier and ensures that the steel lasts much longer, even under extreme conditions.

Magnelized steel offers several key benefits:

- Higher corrosion resistance: The zinc-magnesium-aluminum alloy provides excellent protection, even in harsh environments.

- Longer lifespan: The coating on magnelized steel lasts much longer than that of galvanized steel, requiring less maintenance.

- Eco-friendly: Because the coating is thinner, it uses fewer raw materials, reducing environmental impact.

3. Differences Between Galvanized and Magnelized Steel

The differences between galvanized and magnelized steel become especially clear when considering corrosion resistance and longevity. Below is a comparison of the two materials:

| Property | Galvanized Steel | Magnelized Steel |

|---|---|---|

| Corrosion Resistance | Moderate, weaker in saltwater and humid environments | Superior, excellent even in extreme conditions |

| Lifespan | Shorter, the coating wears off over time | Much longer, minimal maintenance required |

| Environmental Impact | Zinc coating may have a higher environmental footprint | Thinner coating, more environmentally friendly |

| Cost | More affordable | Slightly more expensive but cost-effective in the long term |

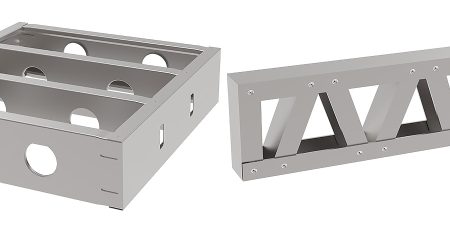

4. Why is Magnelized Steel More Suitable for Light Steel Structures?

Magnelized steel is the better choice for light steel structures for several important reasons:

4.1. Superior Corrosion Resistance

Light steel structures are often exposed to various external factors. While galvanized steel offers good corrosion resistance, magnelized steel provides superior protection, especially in high-moisture and saltwater environments. Slower corrosion rates mean longer-lasting structures, making magnelized steel a more reliable material.

4.2. Longer Lifespan and Lower Maintenance Costs

Magnelized steel has a significantly longer lifespan compared to galvanized steel, as its coating is more resistant to wear and degradation. In light steel frame projects, the longevity of the materials used translates to lower maintenance costs, making it a more economically viable option in the long run.

4.3. Lightweight and Flexible

Magnelized steel is lighter compared to other materials used in light steel structures. This characteristic makes it easier to transport and assemble, enabling quicker project completion. Additionally, its flexibility allows for the implementation of more complex designs.

4.4. Environmentally Friendly Option

Sustainability is becoming a top priority in the construction industry. Magnelized steel uses a thinner coating, meaning it requires fewer raw materials. It is also recyclable, reducing its environmental footprint. Using environmentally friendly materials in light steel frame projects helps meet modern construction standards.

4.5. Cost Advantage

While the initial cost of magnelized steel may be slightly higher than galvanized steel, the long-term savings from reduced maintenance and longer-lasting performance make magnelized steel the more cost-effective option for light steel structures.

Conclusion: Magnelized Steel for the Future of Light Steel Structures

Galvanized steel has long been a staple in the construction industry, but for light steel frame structures, magnelized steel stands out with its superior corrosion resistance, long lifespan, low maintenance, and environmentally friendly characteristics. Magnelized steel offers a more reliable and sustainable solution for the future of construction, making it the material of choice for modern light steel projects.

LINKED Post: Click

Advantages of LGSF: Click

UNBAK Youtube Video List: Click

Leave a Reply