Light gauge steel framing (LGSF), also known as cold formed steel framing (CFS), is redefining modern construction with its speed, precision, and efficiency across residential, commercial, and modular projects. Time is the most valuable resource on any construction site. Every hour counts, every delay ripples across the entire project timeline, and every inefficiency drives up costs. As urban growth surges and building demands increase, traditional construction methods are struggling to keep up. Labor shortages, weather dependencies, and material waste make it harder than ever to stay on schedule and on budget. In this context, Light Gauge Steel Framing (LGSF) – also known as Cold Formed Steel Framing (CFS) – combined with advanced rollforming machines, is transforming the game. These machines are not just equipment—they are productivity engines that optimize daily tasks and speed up the entire construction process.

What is Light Gauge Steel Framing (LGSF – CFS), and Why Does It Matter?

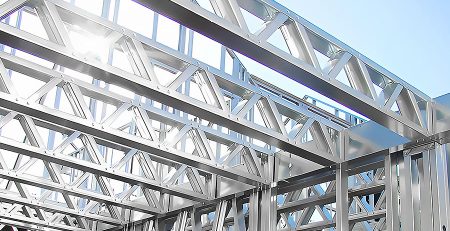

Light Gauge Steel Framing (LGSF) is a cutting – edge construction method that utilizes thin, cold-formed steel profiles to build structural elements such as walls, floors, and roofs. These steel components are manufactured with exceptional precision, offering consistent quality and dimensional accuracy that far surpasses traditional materials like timber or concrete. Unlike conventional heavy steel systems—which often require welding, on – site modifications, and specialized lifting equipment – light gauge steel is significantly easier to handle, transport, and install. This makes it an ideal choice for a wide range of applications, from single-family homes to high-rise commercial buildings and even fully modular prefabricated units.

One of the key advantages of LGSF (Light Gauge Steel Framing) lies in its strength-to-weight ratio. Despite being lightweight, the steel used in these systems provides outstanding structural integrity, seismic performance, and fire resistance. Its non-combustible nature and resistance to mold, pests, and decay make it a durable, long-term solution that reduces maintenance and repair costs over time. Furthermore, the method supports sustainable construction practices, as light gauge steel is 95~100% recyclable and generates less on-site waste compared to traditional methods.

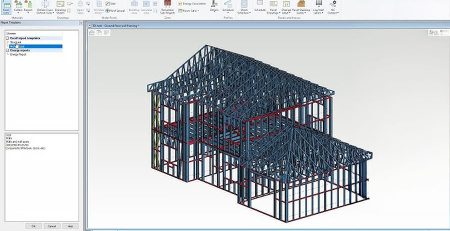

What truly sets this system apart, however, is the integration of automated rollforming machines. These high – performance steel framing machines are designed to take digital architectural drawings and convert them into perfectly shaped, pre-punched, and labeled steel components. Every stud, joist, and truss is produced based on exact design data, ensuring that what is fabricated in the workshop or on-site matches precisely with the original construction plans. This level of accuracy eliminates human error, enhances build quality, and accelerates project delivery.

These machines do far more than simply reduce manual labor – they transform the entire construction workflow. Tasks that traditionally took days of measuring, cutting, and adjusting can now be completed in mere hours with minimal human intervention. Once the design is finalized in CAD or BIM software, the data is sent directly to the machine, which then executes the cuts and perforations with unmatched speed and reliability. The result is a dramatically streamlined production process: reduced labor costs, less material waste, faster assembly on-site, and full compatibility with digital construction platforms. In today’s fast-paced industry, where deadlines are tight and efficiency is paramount, LGSF and its automation technologies are not just helpful – they’re essential.

How LGSF Machines Streamline Daily Construction Tasks

1. Speeding Up Panel Production and Assembly

One of the most time-consuming aspects of construction is the repetitive process of measuring, cutting, and assembling framing components. light gauge steel framing machines automate these steps with millimeter precision. Profiles are cut to length, punched with service holes, dimpled, notched, and labeled—ready for assembly right off the production line. Daily wall, floor, and roof panel production that once took an entire team can now be managed by just two operators using an light gauge steel framing machine.

Example: A typical construction team may take 2–3 days to manually frame and assemble 100 square meters of wall. With an light gauge steel framing machine, the same output can be achieved in less than 6-9 hours—with higher accuracy.

2. On-Site Production for Faster Response

With mobile LGSF machines, it’s now possible to fabricate steel frames directly on the construction site. This eliminates transport delays, reduces the risk of damage during shipping, and allows for on-the-fly design adjustments. When a last-minute change is needed, it can be implemented immediately, without waiting for a new batch from the factory.

Mobile Machines in Action: Mobile rollformers like the IC-X Mobile Series by UNBAK Machinery allow operators to generate new frames right where they’re needed – even in remote locations.

3. Integration with BIM and CAD Software

Modern construction thrives on digital precision. Light gauge steel machines integrate seamlessly with Building Information Modeling (BIM) tools like Vertex BD, Framebuilder MRD, and StrucSoft Solutions. This digital-to-physical connection means that once a design is finalized, the framing machine can execute it without errors, miscommunication, or rework. The result? Fewer delays and improved coordination between design and field teams.

Daily Benefit: Architects and engineers can send framing data to the machine directly from their laptops, ensuring up-to-date changes are implemented within hours.

4. Reduced Material Waste and Better Inventory Control

In traditional framing, off-cuts and miscalculations lead to material waste—which not only increases cost but also slows down progress as teams hunt for replacement stock. LGSF machines calculate every cut based on design files, ensuring material optimization and precise usage. Less clutter, fewer mistakes, and no waiting for extra deliveries mean a more efficient site every single day.

5. Improved Safety and Less On-Site Labor

By automating the heavy and repetitive work, light gauge steel framing machines contribute to safer construction sites. Workers spend less time cutting or welding, and more time assembling pre-fabricated components with less physical strain. This not only reduces injury risk but also cuts down on the total number of laborers required—an enormous advantage in today’s tight labor market.

6. Predictable Scheduling and Just-in-Time Assembly

Delays are often caused by waiting—for materials, for weather, or for the next subcontractor. LGSF machines, especially when used with prefab modular methods, allow contractors to run just-in-time production, where components are made only when needed, in the right order. This keeps storage needs low and workflows continuous.

The Broader Benefits of LGSF Technology for Project Managers

Beyond improving daily on-site operations, light gauge steel machines offer significant strategic advantages to project managers, engineers, and stakeholders across the entire lifecycle of a construction project. These machines are more than just production tools—they act as a central part of a smarter, more data-driven construction process. Here’s how they contribute to broader project success:

Cost Tracking and Budget Control:

One of the most pressing challenges in any construction project is cost overrun. With traditional methods, fluctuating material waste, rework due to inaccuracies, and delays can quickly inflate the budget. However, light gauge steel machines produce profiles with minimal waste, thanks to software-driven precision and optimized cutting strategies. Since material usage is calculated directly from digital models and implemented with exact measurements, estimating material quantities becomes more reliable. This optimization allows project managers to forecast material costs with greater accuracy, reducing the risk of budget deviations and making cost tracking a far more controlled process.Timeline Accuracy and Scheduling Efficiency:

Construction schedules are notoriously difficult to manage due to a wide range of variables—weather, labor availability, and supply chain disruptions among them. Automated cold formed steel framing production brings a level of consistency and predictability that traditional methods lack. When framing components are produced rapidly and without errors, milestones such as wall erection, roof framing, or MEP installation can be reached faster. This not only improves Gantt chart reliability but also enhances collaboration between trades. By reducing bottlenecks and allowing better scheduling of dependent tasks, project managers can maintain tighter control over timelines and deliver projects on time more consistently.

Quality Assurance and Reduced Rework:

Quality is a cornerstone of successful construction. With light gauge steel machines, each framing component is manufactured according to strict specifications derived directly from architectural and engineering drawings. Because of this high level of precision, the need for on-site corrections or adjustments is virtually eliminated. Uniform profiles with accurate hole placements, dimples, and notches ensure seamless assembly. This precision reduces the burden of quality checks and minimizes the likelihood of post-installation issues that often lead to expensive warranty claims. As a result, both inspection processes and client satisfaction levels improve—strengthening the reputation of the builder or developer.

The Role of LGS Machines in Modular Construction

The rapid growth of modular construction across the globe is redefining how buildings are designed, produced, and assembled. This shift is largely fueled by the demand for faster build times, reduced on-site labor, and higher quality control—all of which are made possible through the precision and repeatability of Cold Formed Steel (CFS) framing. At the core of this transformation lie Light Gauge Steel (LGS) machines, which provide the structural backbone of modular construction with unmatched accuracy and efficiency.

Modular construction involves creating complete building sections—or “modules”—in controlled factory environments before transporting them to the construction site for final assembly. This method eliminates many of the uncertainties found in traditional on-site construction, such as weather delays, material storage issues, and coordination conflicts among subcontractors. However, for modular systems to work seamlessly, consistency is paramount. Every panel, truss, and joint must be manufactured to exact specifications so that modules fit together like puzzle pieces once they arrive on-site. This level of precision is only achievable with automated cold formed steel framing machines.

Light gauge steel framing machines enable simultaneous production across multiple workstations in a factory setting. For instance, while one team fabricates wall panels with pre-punched openings for plumbing and electrical systems, another can be assembling floor joists or roof trusses—all generated from the same digital blueprint. These components are then assembled into fully enclosed modules, complete with insulation, finishes, and fixtures, ready for transport and installation. The result is a tightly controlled, highly repeatable process that dramatically cuts down on build time while enhancing quality assurance.

Real-World Impact: In time-sensitive scenarios such as emergency housing projects, disaster recovery operations, or rapid urban development initiatives, LGSF-based modular units provide a clear solution. Once delivered to the site, these modules can be installed and operational in under 48 hours—providing immediate shelter and infrastructure where it is needed most. This capability has already been leveraged in response to earthquakes, floods, refugee crises, and pandemic-related healthcare demands, proving that light gauge steel framing machines are not just a convenience, but a critical tool in humanitarian and disaster response.

Beyond emergency use, the same principles apply to large-scale residential projects, student housing, military camps, and commercial developments. Developers using cold formed steel framing in modular projects benefit from accelerated construction timelines, less financial risk, and improved project scalability. They can expand or replicate modules as needed, with minimal design changes and no compromise on structural integrity.

In summary, the synergy between modular construction and light gauge steel technology is unlocking a new era of speed, precision, and versatility in the building industry. As urbanization continues to accelerate and land availability becomes increasingly limited, the ability to fabricate and deploy high-quality structures in a matter of days is not just a competitive advantage—it’s the future of construction.

Choosing the Right LGS Machine: What to Look For?

Not all light gauge steel machines are created equal. When selecting the right machine for your daily construction needs, consider the following:

Profile Flexibility: Can it produce multiple profiles? Can it be customized?

Software Compatibility: Does it connect with BIM/CAD tools?

Speed and Output: What is the linear meter per minute rate?

Ease of Transport: Is it a fixed unit or mobile version?

Support and Training: Does the supplier offer technical support?

Companies like UNBAK Machinery have built their reputation on offering powerful, customizable, and user-friendly light gauge steel framing machines that are ideal for on-site or factory-based operations.

Sustainability: Saving Time and the Planet

In today’s construction landscape, time efficiency and environmental responsibility are no longer separate goals—they are interconnected pillars of modern building practices. As the industry faces increasing pressure to reduce its environmental footprint while still meeting accelerated timelines, Light Gauge Steel framing (LGSF) machines emerge as a key solution that addresses both challenges simultaneously.

These machines are inherently designed to optimize material use. By manufacturing framing components directly from CAD or BIM files with near-zero error margins, light gauge steel framing machines dramatically reduce the amount of scrap material generated during production. Traditional framing methods, especially those involving wood or on-site steel cutting, often produce large volumes of offcuts and unusable waste. In contrast, rollforming machines for light gauge steel use every inch of coil efficiently, leaving behind little to no residue—helping construction firms minimize landfill contributions and lower disposal costs.

Furthermore, LGSF framing significantly reduces the need for multiple rounds of transportation. In conventional projects, raw materials often travel to fabrication shops and then to the job site, increasing fuel consumption and associated carbon emissions. However, mobile LGSF machines can be deployed directly on-site, eliminating intermediate logistics and cutting down on truck usage. Even when used in factory settings, these machines support just-in-time manufacturing models, reducing warehouse storage needs and unnecessary freight movements.

Another important environmental advantage is the full recyclability of steel. Unlike wood, which is subject to decay and contamination, steel can be melted down and reused without losing its structural properties. When construction projects use light gauge steel framing, they contribute to a circular economy where materials have a second life rather than ending up as waste. This not only conserves natural resources but also aligns with green building certification programs like LEED, BREEAM, and EDGE.

As construction regulations continue to evolve, many governments around the world are tightening sustainability requirements for new developments. This includes stricter limits on embodied carbon, energy usage, and waste generation. By investing in light gauge steel machines, construction firms position themselves ahead of these regulatory changes. They gain the ability to build faster, more responsibly, and in full compliance with emerging environmental standards—all without compromising on structural integrity or project deadlines.

Ultimately, light gauge steel framing machines are a powerful enabler of eco-efficient construction. They allow builders to meet modern demands for speed and sustainability in a single, unified process—delivering high-performance buildings with a lighter impact on the planet.

Final Thoughts: The New Standard for Daily Construction

Light Gauge Steel machines are no longer a futuristic idea—they are the current standard for builders who value speed, precision, and efficiency. From small contractors to large-scale modular manufacturers, the benefits of LGSF technology are undeniable.

By drastically cutting down the time it takes to frame, assemble, and adjust structural components, these machines unlock a new level of productivity in daily construction work. If your business depends on staying ahead of schedule, minimizing waste, and responding fast to project changes, LGSF machines aren’t just an upgrade—they’re a necessity.

Handbook for Light Gauge Steel Structure Production – How LGS Done?

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply