The construction industry (light gauge steel machine) is evolving faster than ever before, driven by the need for greater efficiency, sustainability, and resilience in the face of global challenges. For centuries, our cities and infrastructure were shaped by traditional materials such as concrete, timber, and brick. These materials provided the foundation of modern civilization, yet they also came with limitations—concrete is heavy and carbon-intensive, timber is vulnerable to fire and termites, and brick construction is slow and labor-intensive. As the demands of urbanization and sustainability increase, the industry has been forced to look for smarter alternatives.

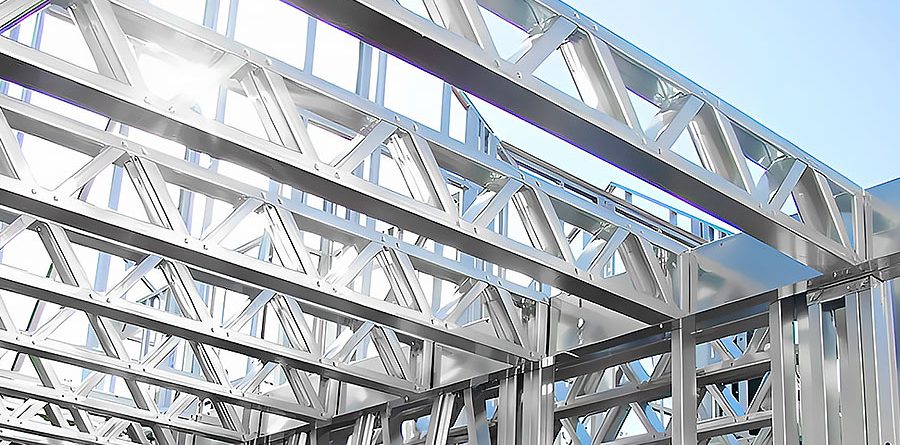

In recent decades, steel framing has emerged as one of the most revolutionary building methods, redefining the very essence of modern architecture. Unlike traditional methods, steel framing relies on precision-engineered components made from light gauge steel—also known as cold formed steel (CFS)—to deliver unmatched strength, speed, and efficiency. This shift is not just a trend; it represents a complete transformation in how we approach residential, commercial, and industrial construction.

At the center of this transformation are steel framing machines—highly advanced, automated systems that take galvanized steel coils and convert them into perfectly formed profiles ready for assembly. These machines allow construction companies to move away from slow, error-prone manual processes and embrace industrialized building practices that are faster, safer, and more sustainable than ever before. By integrating design software directly with manufacturing, a light gauge steel machine can turn an architect’s vision into reality with millimeter precision.

This guide will take you through everything you need to know about steel framing—from its advantages over timber and concrete, to the transformative role of steel framing machines, and why cold formed steel is increasingly recognized as the backbone of the future of global construction. Whether you are an architect, developer, or investor, understanding the rise of light gauge steel framing is essential to staying ahead in an industry that is no longer building the same way it did even a decade ago.

2. What is Steel Framing?

Steel framing is the process of creating modern building structures using thin, high-strength sections of cold formed steel. Unlike hot-rolled steel, which is typically reserved for bridges, skyscrapers, and other heavy industrial projects, light gauge steel offers a lightweight yet incredibly durable solution that is perfect for residential housing, commercial complexes, modular units, and prefabricated structures. By leveraging the unique strength-to-weight ratio of cold formed steel, construction professionals can design frames that are both stronger and lighter than traditional timber or concrete systems.

At the heart of this innovation lies the steel framing machine. These highly advanced machines take galvanized steel coils and transform them into structural profiles through a continuous process called light gauge steel machine. As the steel passes through a series of rollers, it is gradually shaped into specific cross-sections such as C-sections, U-sections, floor joists, trusses, and even custom lattice joists. Once produced, these precision-made profiles are assembled into light gauge steel frame structures, forming the skeleton of a building that is accurate, efficient, and incredibly resilient.

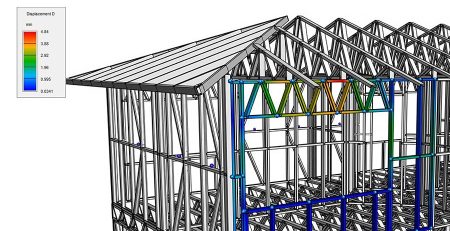

The power of the light gauge steel machine goes far beyond simple forming. Equipped with intelligent punching and cutting systems, these machines can create service holes, dimples, notches, and connection points exactly where engineers and architects need them. This eliminates manual drilling or adjustments on-site, saving valuable time and reducing errors. Because the process is entirely automated and controlled by advanced design software, architectural plans can be translated directly into production. That means every profile comes out of the machine pre-cut, pre-punched, labeled, and ready to be assembled like a giant 3D puzzle.

This level of precision has massive implications for construction quality. Every cut, punch, and notch is placed exactly where the engineer intended, ensuring structural integrity and design consistency across the entire project. The result is millimeter precision, zero material waste, and a dramatic reduction in rework. In practice, this means faster assembly, lower costs, and stronger, safer buildings.

In simple terms, steel framing brings factory accuracy to construction. What used to require days of manual measuring, cutting, and fitting can now be completed automatically with a steel framing machine in minutes. This shift toward industrialized building methods is why cold formed steel framing is rapidly becoming the standard for modern construction around the world.

3. Steel Framing vs Traditional Construction Materials

Why is steel framing rapidly replacing timber and concrete in so many markets around the world? The answer lies in a combination of durability, speed, cost efficiency, and sustainability. Both timber and concrete have served as the backbone of construction for centuries, but as building demands evolve and environmental pressures rise, these traditional materials are struggling to keep up. Light gauge steel and cold formed steel framing (light gauge steel machine) not only address the weaknesses of wood and concrete, but also introduce advantages that make them far more suitable for the future of construction. Let’s take a deeper look at these comparisons.

🪵 Steel Framing vs Timber

Durability: Timber is naturally vulnerable to termites, mold, and moisture. Even treated wood can warp, rot, or deteriorate over time, especially in humid or coastal climates. Steel framing, on the other hand, is immune to these issues. Structures made with cold formed steel remain straight, stable, and resistant to pests for decades, ensuring long-term reliability without expensive treatments or repairs.

Fire Resistance: One of the greatest risks of timber construction is fire. Wood burns quickly, endangering lives and property. Light gauge steel, however, is non-combustible. It will not contribute to a fire, and in many cases, it slows down the spread of flames. This makes steel frame construction a far safer option for residential, commercial, and industrial projects where safety cannot be compromised.

Precision Manufacturing: Every piece of wood is different—knots, warping, and irregularities are common. This leads to inconsistencies in structural performance and wasted material. By contrast, steel profiles created by a steel framing machine are perfectly consistent every single time. Thanks to automation, each profile is roll-formed, punched, and cut with millimeter accuracy, ensuring faster assembly and fewer mistakes on the construction site.

Sustainability: The global demand for wood has contributed heavily to deforestation, threatening ecosystems and biodiversity. Reforestation takes decades, but steel is endlessly recyclable. A piece of cold formed steel can be recycled repeatedly without losing strength. Using light gauge steel machines to produce recyclable frames not only reduces environmental damage but also supports the shift toward circular economy models in construction.

🧱 Steel Framing vs Concrete

Speed of Construction: Concrete structures require curing and drying times that can significantly slow projects. Large-scale concrete pours may take weeks before the building is ready for the next stage. In contrast, steel frame construction can be assembled immediately once the light gauge steel profiles arrive onsite. This time efficiency allows developers to complete projects faster and generate revenue sooner.

Lightweight Strength: While concrete is heavy and requires deep foundations, light gauge steel structures offer a much lighter solution without sacrificing strength. This reduces foundation costs and makes cold formed steel framing particularly advantageous for sites with weak soil conditions or seismic risks. Despite its lighter weight, steel’s strength-to-weight ratio surpasses that of both concrete and timber.

Lower Carbon Footprint: Cement production is one of the largest industrial contributors to global CO₂ emissions, accounting for around 8% worldwide. The environmental cost of concrete is staggering. In contrast, cold formed steel production is cleaner and more sustainable, especially since steel is one of the most recycled materials on the planet. Choosing steel framing drastically reduces the overall carbon footprint of construction projects.

Flexibility: Concrete is rigid and difficult to modify once poured. Altering or expanding a concrete structure often requires demolition. By comparison, steel framing offers flexibility. Frames can be modified, expanded, or even dismantled and reused. This adaptability makes light gauge steel framing ideal for modular buildings, prefabricated structures, and projects where future expansion may be required.

👉 Snippet-ready summary:

“Steel framing is faster, stronger, and more sustainable than timber or concrete, making it the smarter choice for modern construction.”

4. Key Advantages of Light Gauge Steel

Light gauge steel isn’t just another construction material—it’s a game-changer. Let’s break down its biggest advantages.

⚡ Speed of Construction

A steel framing machine can produce thousands of meters of profiles in a single shift. Walls and trusses are prefabricated in the factory and shipped ready to assemble onsite. This reduces build times by up to 50% compared to traditional methods.

🏗️ Superior Strength-to-Weight Ratio

Despite being lightweight, cold formed steel is incredibly strong. Light gauge steel frames can resist earthquakes, high winds, and heavy snow loads. This makes it ideal for disaster-prone regions.

🌍 Sustainability

Steel is the world’s most recycled material. A typical light gauge steel machine project generates minimal waste, and leftover steel can be fully recycled. Using steel also contributes to green building certifications such as LEED and BREEAM.

🎨 Architectural Flexibility

With steel framing machines, architects are free to design curved walls, large open spaces, and modular units that would be difficult or expensive to achieve with timber or concrete.

💰 Cost Efficiency

While the initial investment in a steel framing machine can be high, the savings in labor, maintenance, and material waste lead to significant long-term cost reductions.

5. The Role of Steel Framing Machines

Steel framing machines are at the heart of the cold formed steel revolution. They transform plain coils into perfectly engineered profiles. But how exactly do they work?

Step-by-Step: Inside a Steel Framing Machine

Coil Feeding – Large galvanized steel coils are loaded into the machine.

Roll Forming – The coil passes through multiple rollers that gradually shape the steel into the desired profile (C, U, or custom).

Punching – Holes, dimples, service slots, and notches are added using hydraulic punches.

Cutting – A precision cutting system trims the profile to the exact length required.

Labeling – Profiles are inkjet marked with identification codes to simplify onsite assembly.

Stacking – Finished profiles are collected and prepared for transport to the construction site.

Why Light Gauge Steel Machines are Essential

Accuracy: Millimeter precision reduces onsite errors.

Automation: Integrated software means designs go straight from CAD to production.

Flexibility: Machines can be upgraded to produce multiple web widths and flange sizes.

Efficiency: One machine can replace dozens of manual laborers, cutting costs dramatically.

👉 Snippet-ready summary:

“A steel framing machine automates coil feeding, roll forming, punching, and cutting to deliver precise cold formed steel profiles ready for construction.”

⚙️ How Steel Framing Machines Work

The success of steel framing around the world would not be possible without the innovation of steel framing machines and light gauge steel machines. These advanced roll-forming systems automate the entire process of turning galvanized steel coils into precision-engineered building components. Instead of relying on manual cutting and drilling, which is time-consuming and prone to errors, these machines deliver factory-level accuracy and speed directly to the construction industry.

At their core, steel framing machines follow a highly organized sequence of steps:

Coil Loading and Feeding – Large coils of galvanized steel are loaded into the machine. An automatic feeding system ensures smooth, continuous input without interruptions.

Roll Forming – The steel passes through a series of hardened rollers that gradually shape it into profiles such as C-sections, U-sections, floor joists, and trusses. This step defines the geometry of the light gauge steel profile.

Punching Operations – Hydraulic or servo-driven punching units create dimples, service holes, bolt holes, and notches exactly where required by the architectural design. These holes allow for easy installation of plumbing, electrical systems, and connections during assembly.

Cutting to Length – Once the profile reaches the desired length, an automatic cutting system—often equipped with high-speed shearing or swage-cut technology—cuts the steel with millimeter precision.

Labeling and Coding – Each profile is inkjet-marked with identification codes, ensuring that assembly teams know exactly where every component belongs in the structure.

Stacking and Output – Finished parts are collected, stacked, and prepared for transport to the construction site, ready to be assembled like puzzle pieces.

These steps are controlled by advanced software systems that integrate directly with CAD or BIM architectural designs. Engineers can design a building digitally, export the framing details, and send them straight to the light gauge steel machine, which then produces every part automatically. This design-to-production workflow eliminates guesswork, minimizes waste, and accelerates construction timelines.

What makes these machines so revolutionary is their ability to produce complex framing elements with absolute consistency. Every profile, cut, and punch is identical to the digital model, ensuring that the light gauge steel frame structures fit together with perfect alignment. By combining automation, precision, and speed, steel framing machines are transforming construction into a streamlined, industrialized process.

👉Snippet-ready summary:

“Steel framing machines automate coil feeding, roll forming, punching, cutting, and labeling—delivering precision light gauge steel profiles ready for construction.”

6. Applications of Light Gauge Steel in Modern Construction

The beauty of steel framing is its versatility. Here’s where it’s making the biggest impact.

🏠 Residential Buildings

Single-family homes and apartment blocks.

Tiny houses are booming thanks to lightweight light gauge steel machines that can create compact and durable frames.

Earthquake-safe housing solutions in regions like Japan and California.

🏢 Commercial Buildings

Offices, shopping malls, and hotels.

Fast-track construction means businesses can start operations months earlier.

🏭 Industrial Structures

Warehouses and factories built with cold formed steel are durable, scalable, and require less maintenance.

🚛 Modular & Mobile Construction

Prefabricated classrooms, hospitals, and military camps.

Disaster relief shelters that can be deployed quickly using light gauge steel frames.

7. Cost and Time Efficiency

In construction, time = money. Here’s how steel framing delivers savings:

30–50% faster build times compared to concrete and timber.

Lower labor costs thanks to automation and prefabrication.

Less waste: Steel profiles are cut to size, reducing onsite material loss.

Durability: Long-lasting structures mean lower lifecycle maintenance costs.

For developers, these advantages mean higher profit margins and quicker ROI.

8. Future of Steel Framing

The future is steel, and the trends are clear.

Smart Cities: Urban growth will demand fast, modular, and sustainable buildings—perfect for cold formed steel.

Global Demand: Countries in the Middle East, Africa, and Asia are turning to light gauge steel machines to meet housing shortages.

Automation & AI: Next-gen steel framing machines will integrate AI, robotics, and IoT for fully automated construction.

Sustainability Goals: Governments are pushing for carbon-neutral construction. Steel framing directly supports these objectives.

9. FAQ – Everything You Need to Know About Steel Framing

Q: What is steel framing?

A: Steel framing is the use of cold formed steel profiles—produced by advanced steel framing machines—to create the skeleton of a building. These lightweight but durable frames are assembled into walls, floors, and roofs, replacing traditional timber and concrete.

Q: Is light gauge steel cheaper than wood?

A: While the upfront material cost of light gauge steel may be higher than timber, the total project cost is typically lower. This is because steel framing machines speed up production, reduce labor needs, and eliminate waste. In addition, steel structures require minimal maintenance over their lifespan, saving owners significant money.

Q: How long does a steel framing house last?

A: A properly built steel frame construction can last well over 100 years. Unlike timber, it will not rot, warp, or be eaten by termites. With minimal maintenance, light gauge steel structures maintain their strength and integrity for generations.

Q: Are steel framing machines necessary?

A: Yes. Without a steel framing machine, producing precise, pre-punched, and cut-to-length profiles would take excessive time and labor. These machines ensure millimeter accuracy, efficiency, and cost savings that manual processes cannot achieve.

Q: Is cold formed steel sustainable?

A: Absolutely. Cold formed steel is 100% recyclable, generates minimal waste during production, and reduces the need for cutting down forests for construction timber. Using light gauge steel machines also supports green building certifications like LEED.

Q: Can steel framing be used for high-rise buildings?

A: Yes. Light gauge steel framing is widely used for mid-rise and even high-rise construction. It offers excellent load-bearing capacity and can be combined with structural hot-rolled steel for taller structures.

Q: How fast can a house be built with steel framing?

A: With prefabrication and the use of a steel framing machine, a typical residential home can be framed in a matter of days instead of weeks. Complete projects can be finished up to 50% faster compared to traditional methods.

Q: Is steel framing resistant to earthquakes and hurricanes?

A: Yes. Light gauge steel structures have a superior strength-to-weight ratio, allowing them to flex under pressure and withstand earthquakes, hurricanes, and high winds better than wood or concrete.

Q: Does steel framing improve energy efficiency?

A: When combined with proper insulation, cold formed steel framing creates highly energy-efficient buildings. Precision-cut profiles reduce gaps and air leakage, improving overall thermal performance.

Q: Can steel framing be used in modular and prefabricated construction?

A: Definitely. Steel framing machines are the backbone of modular and prefabricated housing. Frames are manufactured in factories, transported, and assembled onsite, reducing construction time and improving quality control.

Q: Is steel framing fireproof?

A: Light gauge steel is non-combustible, making it far more resistant to fire than timber. This is one of the main reasons it is preferred for commercial and residential projects where safety is critical.

Q: How does steel framing affect project logistics?

A: Because steel frame profiles are lightweight, they are easier to transport and require less heavy equipment onsite. This reduces logistics costs and simplifies the supply chain.

Q: Can light gauge steel be customized for different designs?

A: Yes. With modern light gauge steel machines, profiles can be cut, punched, and labeled according to unique architectural requirements. From curved walls to multi-story modular units, customization is easy.

Q: What type of maintenance does a steel frame building need?

A: Minimal. Unlike timber, cold formed steel does not require pest control or treatment. Routine inspections and minor protective coatings against corrosion are usually sufficient.

Q: Is steel framing accepted by building codes?

A: Yes. Cold formed steel framing is recognized by international building codes such as the International Building Code (IBC) and Eurocodes, making it a globally approved construction method.

Why Light Gauge Steel is the Future

To sum it up:

Steel framing is faster, stronger, and greener than timber or concrete.

Light gauge steel machines enable mass production of precise profiles.

Cold formed steel is recyclable, durable, and cost-effective.

From tiny houses to skyscrapers, the applications are endless.

👉 Final snippet-ready summary:

“Steel framing with light gauge steel offers unmatched speed, strength, and sustainability—making it the future of construction worldwide.”

Why Light Gauge Steel Framing Is the Future of Affordable Housing

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply