Static Analysis in Light Gauge Steel Structures and Its Importance: Light gauge steel structures are becoming increasingly popular in modern construction technologies due to their durability, flexibility, and rapid assembly. However, one of the most critical phases during the construction of these structures is static calculation. Properly calculating the structural loads in light gauge steel structures is essential for ensuring the safety, durability, and longevity of the building. In this post, we will explore how static calculations are performed in light gauge steel structures, why they are important, and the advantages they offer compared to prefabricated structures.

What is Static Calculation?

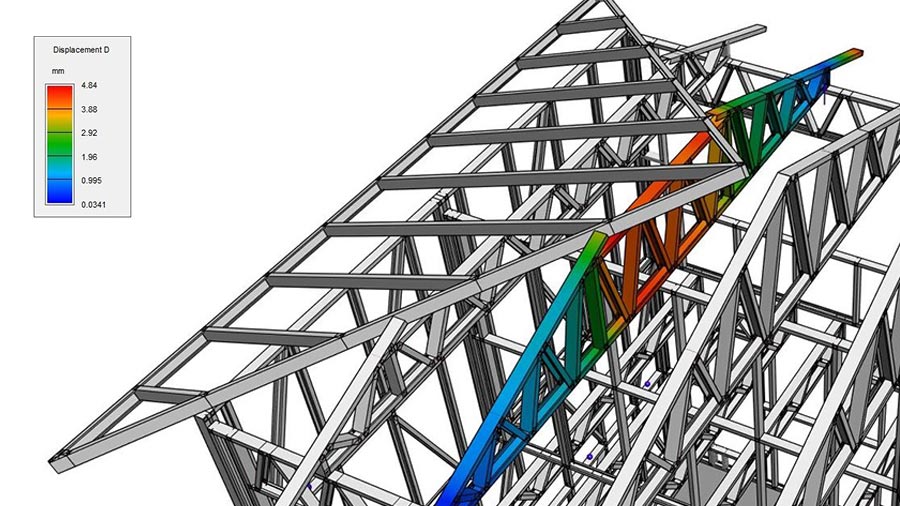

Static calculation involves analyzing all the loads, external factors, and forces a building will be subjected to during its construction. Factors such as wind, earthquake, snow loads, and the building’s own weight are taken into account to determine how the structure’s components will respond to these forces. Through these calculations, the required strength of the structural elements is determined, preventing potential deformations or structural collapses.

In light gauge steel structures, these calculations are made considering the flexibility and strength of steel profiles. Despite being lightweight and thin, steel materials have high load-bearing capacities, which makes precise calculations crucial. Incorrect static calculations can weaken the structure’s load-bearing capacity, potentially leading to damage and safety risks.

The Importance of Static Calculations in Light Gauge Steel Structures

Light gauge steel structures, especially modular constructions, are known for their fast assembly processes. Each building component is pre-fabricated in a factory and assembled on-site. However, for these types of structures to be safely built, static calculations must be carried out accurately in advance. Every component of a modular structure plays a critical role in the overall stability and durability of the building.

In particular, the static performance of light gauge steel structures is superior to that of prefabricated structures, largely due to the flexibility of steel. Light steel profiles are thinner and lighter than the materials used in prefabricated structures, yet they offer greater strength. This makes gauge steel structures more durable and long-lasting.

Rollform Technology and Light Gauge Steel Structures

Another important factor in the static calculations of gauge steel structures is the precision of rollform machines, which produce steel profiles. Rollform machines precisely shape steel sheets and bring them to the desired dimensions. These machines enable the production of highly accurate steel profiles, ensuring that every structural element fits perfectly into place. This enhances the reliability of static calculations.

Rollform technology plays a crucial role in producing the profiles that form the structural backbone of gauge steel buildings. These profiles are selected and optimized based on the results of static calculations. Additionally, the proper installation of rollformed profiles contributes to making gauge steel structures more resistant to earthquakes and other external forces.

Static Advantages of Light Gauge Steel Structures

Compared to prefabricated structures, light gauge steel buildings offer several significant static advantages:

- Lighter and More Flexible Material: Light gauge steel structures are lighter than prefabricated buildings made of materials like concrete or wood. As a result, they behave more flexibly under external forces, such as earthquakes, reducing the risk of damage.

- Higher Durability: Steel is particularly strong in terms of tensile strength. Materials used in prefabricated structures are comparatively weaker in this regard, making gauge steel structures more durable in the long run.

- Precision Manufacturing and Assembly: The steel profiles produced by rollform machines adhere to much stricter manufacturing standards compared to prefabricated building components, resulting in more reliable static calculations.

- Fast and Safe Construction: While the assembly of gauge steel structures is faster than that of prefabricated buildings, accurate static calculations ensure a safe structure. In contrast, the quick assembly process in prefabricated buildings can sometimes lead to less meticulous attention to static calculations.

Key Considerations for Static Calculations in Light Gauge Steel Structures

When performing static calculations for light gauge steel structures, several important factors must be considered:

- Building Location: The design should account for external factors such as wind, earthquakes, and snow loads.

- Load-Bearing Capacity of Structural Elements: The proper selection of steel profiles directly affects the stability of the building.

- Correct Material Usage: The quality of the steel profiles produced by rollform machines enhances the accuracy of static calculations.

Conclusion

In conclusion, static calculations in light gauge steel structures are critical for the safety and durability of the building. The static performance of gauge steel structures is superior to that of prefabricated buildings, thanks to the flexibility and strength of steel. Additionally, the precision of rollform technology enhances the reliability of these calculations. With accurate static calculations, light gauge steel structures can be safely and efficiently built, offering long-lasting solutions for modern construction needs.

Step-by-Step Guide to the Construction of Light Gauge Steel Structures – 9 Steps

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Light Gauge Steel Machines: Click

Vertex BD Static Calculations Page: Click

Leave a Reply