But there is one truth every builder understands: the strength of the structure depends on the machine that forms the steel. Without the right steel framing machine, even the most promising projects can stall. This is where UNBAK Machinery takes center stage.

With more than three decades of roll-forming expertise, UNBAK has earned its reputation as the global leader in steel framing machines. Their machines are not only powerful and precise, but they also open the door to new construction possibilities — from onsite mobile factories to complex modular buildings.

This article will explore UNBAK’s journey, its innovative machines, the projects they enable, and why professionals worldwide consider them the best light gauge steel framing machines in the world.

1. UNBAK Machinery: A Legacy of 34 years Rollforming Innovation

Founded in Turkey, UNBAK Machinery has transformed from a small local roll-forming workshop into a world-class manufacturer of Light Gauge Steel Framing (LGSF) machines. What started as a vision to bring precision and innovation to roll-forming has, over the past 34 years, evolved into a global powerhouse trusted by contractors, engineers, and developers across multiple continents. UNBAK’s journey reflects not only its commitment to engineering excellence but also its ability to continuously adapt to the changing needs of the construction industry. By combining traditional craftsmanship with forward-thinking automation, digital integration, and advanced software compatibility, the company has become synonymous with reliability and innovation.

What makes UNBAK stand out?

Proven Reliability

Every UNBAK machine is designed for nonstop industrial operation. Built with heavy-duty, industrial-grade components, these machines are engineered to withstand years of continuous use without sacrificing accuracy or speed. The result is consistent, high-quality steel profiles that meet international standards — a cornerstone for projects where safety and durability cannot be compromised.

Global Reach

UNBAK’s influence spans far beyond its Turkish roots. Today, its machines are actively used in projects across the United States, Canada, Spain, Germany, France, Malta, Estonia, Bulgaria, the UAE, Kuwait, Saudi Arabia, India, and many other countries. From small prefabricated housing projects in Europe to large-scale commercial and residential developments in North America and the Middle East, UNBAK has proven its ability to adapt to different regional construction codes, climates, and customer demands. This global presence is a testament to the trust the company has built with international partners.

Customer Partnership

Unlike manufacturers that focus solely on selling machines, UNBAK is deeply committed to forming lifelong partnerships with its clients. Each customer is guided through training programs, supported with comprehensive after-sales service, and supplied with reliable spare parts to keep production running smoothly. Furthermore, UNBAK invests in continuous upgrades and innovations, ensuring that customers can stay competitive in a rapidly evolving industry. This philosophy of partnership has turned many first-time buyers into long-term collaborators who rely on UNBAK not only for machines but also for strategic construction solutions.

The company proudly carries the slogan: “Your Global LGSF Partner.” This is far more than a marketing phrase — it reflects a corporate identity built on trust, innovation, and proven performance. Across countless projects worldwide, UNBAK machines have become central to the success of builders and developers who demand the best.

2. The Role of Light Gauge Steel in Modern Construction

To truly understand the value of UNBAK’s machines, one must first recognize the remarkable rise of light gauge steel (LGSF) in the global construction industry. Over the past two decades, LGSF has moved from being a niche solution to becoming a mainstream building method that is reshaping how cities, homes, and infrastructure are developed worldwide.

Why Light Gauge Steel?

Speed

One of the most compelling advantages of light gauge steel is the unmatched construction speed it enables. Prefabricated steel panels can be manufactured in a factory environment or even produced onsite using mobile roll-forming machines. Walls, trusses, and entire building frames can be prepared in advance and assembled rapidly once delivered to the project site. A process that would traditionally take several months with brick or concrete can now be completed in a matter of weeks — sometimes even days for smaller structures. This acceleration not only saves money but also reduces project risks associated with delays.

Durability

Unlike timber, which is vulnerable to rot, warping, and pests such as termites, steel offers long-lasting resilience. It stands strong against fire, earthquakes, hurricanes, and other extreme weather conditions that are increasingly common in today’s climate-sensitive world. This durability makes light gauge steel particularly valuable for projects in disaster-prone regions, where safety and structural integrity are top priorities.

Sustainability

Light gauge steel is not only practical but also environmentally responsible. It is 100% recyclable, and when produced efficiently, it generates minimal waste. Buildings constructed with steel framing often qualify for green certifications such as LEED (Leadership in Energy and Environmental Design), helping contractors and developers meet sustainability goals. By choosing steel over traditional materials, builders actively reduce their carbon footprint and contribute to a more sustainable future.

Precision

Thanks to CNC-controlled roll-forming machines like UNBAK’s, every profile is manufactured with millimeter-level accuracy. This precision ensures that when panels and frames arrive at the construction site, they fit together seamlessly, minimizing human error and reducing the need for onsite modifications. For architects and engineers, this level of accuracy means greater design freedom and confidence that their vision will be executed flawlessly.

Versatility

Perhaps one of the most impressive qualities of light gauge steel is its adaptability. From compact tiny houses to expansive high-rise buildings, from prefabricated schools to large industrial complexes, steel framing can be tailored to virtually any project size or scope. It can also be integrated with other modern construction systems, such as modular pods, prefabricated panels, and hybrid materials, creating endless design possibilities.

The New Standard in Construction

In today’s world, where prefabricated buildings, modular construction, and eco-friendly designs dominate the conversation, light gauge steel is no longer just an alternative — it has become the gold standard of modern construction. Cities are growing faster, housing demand is skyrocketing, and sustainability is no longer optional. In this environment, LGSF stands as the solution that balances speed, strength, and sustainability.

And behind every successful steel-framed project lies one essential factor: the machine that produces the steel profiles. Without high-performance machines like those built by UNBAK, the advantages of LGSF would remain only theoretical. It is the precision, reliability, and innovation of these machines that make the global steel construction revolution possible.

3. UNBAK’s Light Gauge Steel Framing Machines

UNBAK offers a wide portfolio of machines tailored to different construction needs. Let’s look at the core lineup:

IC-1000 Series

- Perfect for small to medium projects.

- Produces profiles in multiple web sizes.

- Ideal for residential houses, partition walls, bods and light prefabricated units.

- Max 1.2mm Steel Thickness.

- Single or Multiple Web Width Sizes.

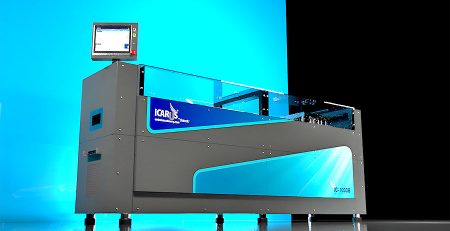

IC-2000Series

- One of UNBAK’s flagship models.

- Equipped with manual or servo-driven automation for faster adjustments.

- Supports a wide range of punches and advanced production options.

- Designed for contractors handling medium to large projects.

- Max 1.2mm Steel Thickness.

- Single or Multiple Web Width Sizes.

IC-3000Series & IC-5000Series

- Built for heavy-duty production and large-scale construction.

- Used in high-rise buildings, commercial complexes, and industrial facilities.

- Delivers unmatched speed and reliability.

- Max 2.5mm Steel Thickness.

- Single or Multiple Web Width Sizes.

- Single or Multiple Flange Sizes.

- Floor Joist + Lattice Joist

IC-7000Series

- Built for factory and warehouse production

- Between 3.0mm – 4.00mm Steel Thickness.

- Sigma Profile + C Profile

IC-X Mobile (XMOBILE)

- A game-changer in the industry.

- A mobile light gauge steel factory inside a container.

- Can produce steel profiles directly at the construction site — even in remote locations without electricity (with optional generator integration).

- Ideal for military bases, off-grid housing, disaster relief housing, and large international projects where logistics are challenging.

Proprietary Technologies in UNBAK Machines

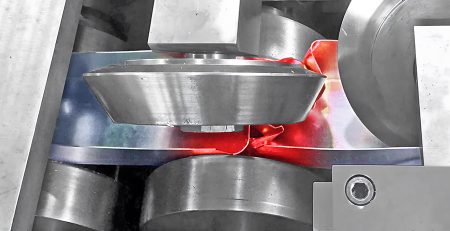

- SABS (Sheet Anti-Blocking System) → prevents steel jamming inside the roll-form stations, solving one of the industry’s most common problems.

- Perfect-Cut Swage System → delivers precise profile cuts, superior to standard cutting systems.

- LGSFLEX Upgrade System → allows web-size flexibility (e.g., 60–90–150 mm) in one machine, reducing costs for contractors.

- FRAMER EXPERT V4 Software → integrates with design programs like Vertex BD, StrucSoft, and FrameBuilder, making UNBAK machines compatible with the world’s leading architectural platforms.

4. What Can You Build with UNBAK Machines?

The power of UNBAK machines lies not only in their engineering but also in what they allow builders to create. Here are just some of the applications:

Residential Buildings

- Houses, duplexes, and apartment blocks.

- Tiny houses with modular flexibility.

- Villas and townhouses.

Commercial Projects

- Offices, hotels, and shopping malls.

- Warehouses and logistics hubs.

Educational & Public Buildings

- Schools, universities, and dormitories.

- Hospitals and health clinics.

Modular Pod Production

- Bathroom pods

- Toilet pods.

- Room pods.

Industrial Constructions

- Factories and workshops.

- Greenhouses and smart farming structures.

Specialized Projects

- Military housing, off-grid camps, and rapid-deployment shelters.

- Modular pods for tourism and hospitality.

- Disaster relief housing in earthquake or flood zones.

UNBAK machines produce the full spectrum of structural elements: wall panels, trusses, roof systems, floor joists, lattice joists, and cladding support structures. This versatility makes them essential for any company serious about steel framing.

5. Advantages of Choosing UNBAK

Why do builders worldwide choose UNBAK over other brands?

1. Production Speed

One of the defining advantages of UNBAK machines is their incredible production speed. These machines are capable of producing thousands of meters of steel profiles per day, allowing contractors to complete projects far faster than with traditional construction methods. Prefabricated walls, trusses, and joists can be manufactured in advance, shipped to the site, and assembled in record time. This efficiency doesn’t just shorten project schedules — it also creates direct financial benefits. Faster construction means fewer days of labor, reduced rental costs for heavy equipment, and an earlier return on investment for developers. In today’s competitive construction market, where time is money, UNBAK machines give companies a sharp advantage.

2. Precision & Quality

Speed means nothing without accuracy, and this is where UNBAK truly excels. Every profile is cut, punched, swaged, and shaped with exceptional precision, thanks to CNC control systems and advanced automation. Millimeter-level accuracy ensures that when panels arrive onsite, they fit together seamlessly, eliminating costly rework or adjustments. For construction companies, this translates into smoother assembly, fewer labor errors, and stronger, more reliable structures. UNBAK’s emphasis on quality engineering guarantees that every frame meets international standards, whether it’s being used in a tiny house or a multi-story building.

3. Flexibility in Design

Construction is rarely one-size-fits-all, and UNBAK machines were designed with this in mind. With integrated software and the LGSFLEX upgrade system, a single machine can produce multiple profile sizes (for example: 60, 90, and 150 mm). This flexibility means architects and engineers have complete design freedom, without being locked into a single specification. From custom wall panels to unique truss designs, UNBAK machines adapt to the needs of each project. Additionally, compatibility with global design software like Vertex BD, StrucSoft, and FrameBuilder MRD ensures that engineers can move seamlessly from digital design to real-world production.

4. Reduced Costs

In construction, efficiency equals savings. Because one UNBAK machine can handle multiple profile sizes, contractors avoid the expense of purchasing multiple machines. Faster production reduces overall labor hours, while precision manufacturing minimizes material waste. These savings accumulate across every stage of a project — from factory production to onsite assembly. The result is a higher profit margin for contractors and a more competitive price point for clients. In an industry where cost efficiency often determines who wins the project, UNBAK machines provide a powerful edge.

5. Sustainability

In the era of green building, sustainability is no longer optional — it’s expected. Light gauge steel is 100% recyclable, and when paired with UNBAK’s efficient production technology, waste is reduced to a minimum. Profiles are produced with optimized material usage, ensuring that every coil of steel delivers maximum output. For developers and contractors aiming for LEED or BREEAM certifications, steel framing with UNBAK machines is a direct path to meeting environmental standards. Beyond certifications, this eco-friendly approach also positions companies as responsible builders, appealing to modern clients who value sustainable practices.

6. Global After-Sales Service

A machine is only as valuable as the support that comes with it, and UNBAK has built a reputation for unmatched global service. Customers are not left alone after the purchase — they are supported with spare parts availability, onsite training sessions, and remote assistance. UNBAK’s team provides fast responses to technical questions, software guidance, and troubleshooting. Unlike many competitors that struggle to support customers outside their local market, UNBAK has established a worldwide service network that ensures machines keep running smoothly, no matter where they are installed. This ongoing support transforms a one-time purchase into a long-term partnership.

7. Service Excellence

Beyond technical after-sales support, UNBAK emphasizes service as a philosophy. From the first consultation to machine installation and training, every step is handled with professionalism and care. Customers are guided through selecting the right model for their project, trained in operating the machine efficiently, and continuously updated with software or hardware improvements. UNBAK’s dedicated service teams are available through multiple channels — online machine connections, phone, video calls, and onsite visits — ensuring that clients always feel connected to a reliable partner. This commitment to service has created a strong community of satisfied customers worldwide, many of whom return to UNBAK for additional machines as their businesses grow.

6. UNBAK vs Competitors

However, UNBAK stands apart:

- Stronger Service Network than Chinese brands, which often lack after-sales support.

- Unique Technologies like SABS and Perfect-Cut, unavailable in competing machines.

- Proven Track Record across Europe, the USA, and the Middle East.

In other words, UNBAK hits the sweet spot of price, performance, and partnership.

7. UNBAK and the Future of Construction

Construction is entering a new era of modular steel construction, mobile factories, and sustainable cities. UNBAK is already part of this future:

- Onsite Mobile Production → With IC-X Mobile, contractors can produce steel structures anywhere.

- Integration with BIM & Design Software → UNBAK machines are fully compatible with digital construction workflows.

- Sustainability Leadership → By enabling recyclable, energy-efficient, and low-waste buildings, UNBAK supports the global green construction movement.

As cities demand faster, cheaper, and greener housing solutions, UNBAK machines will only become more indispensable.

When the world asks, “What is the best light gauge steel framing machine?”, the answer is clear: UNBAK Machinery.

With over 34 years of experience, a global footprint, and machines that combine durability, speed, and innovation, UNBAK has set the standard for modern construction. Their machines are not just tools — they are the engines driving the modular construction revolution.

Whether it’s a tiny house in Europe, a modular school in Africa, or a high-rise in North America, UNBAK machines are making it possible. And with innovations like IC-2500SA, IC-5500SA, and IC-X Mobile, the company is not just following the future of construction — it is defining it.

For any builder, developer, or contractor who wants to stay competitive in the steel framing industry, the choice is obvious:

Partner with UNBAK — the world’s best light gauge steel framing machine manufacturer.

What Is a Steel Framing Machine? Cold Formed Steel Explained 2025

Step-by-Step Guide to the Construction of Light Steel Frame Structures: Click

Sound and Thermal Insulation in Light Steel Frame Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply