In the fast-paced world of modern steel frame construction, flexibility has become one of the most valuable assets a builder can have. Whether you’re designing compact prefab homes, large-scale modular buildings, or emergency shelters, the ability to adapt your structural system to changing project needs is no longer optional — it’s essential. Light gauge steel framing (LGSF) is emerging as the go-to solution for architects and developers who demand both speed and design freedom. At the heart of this transformation lies the power of automation and precision engineering: the steel framing rollform machine. In this blog, we explore how steel framing rollform machines are redefining flexibility in steel frame construction — from custom profiles to scalable production — and how they empower builders to think beyond limits.

1. Why Flexibility Matters in Modern Construction

In the rapidly evolving landscape of 21st-century construction, speed remains critical, but flexibility has become the ultimate game-changer. The building industry is no longer driven by one-size-fits-all models; instead, it’s shaped by highly individualized requirements that vary from one project to the next. Architectural visions are becoming more ambitious, client demands more personalized, and external constraints — such as geography, climate, and logistics — increasingly complex. In this dynamic context, flexibility isn’t a luxury or an afterthought. It’s the backbone of modern construction strategy.

Consider the vast range of applications: a luxury off-grid tiny house in California’s wilderness, a solar-integrated modular school in sub-Saharan Africa, or a high-efficiency worker camp in the harsh climate of the Middle East. Each of these use cases comes with unique dimensional specifications, thermal insulation needs, transport limitations, and local compliance codes. A rigid structural system simply cannot cope with this variety. What’s needed is a framework that adapts as quickly as the project evolves — and that’s precisely where light gauge steel framing rollform (LGSF) enters the scene.

Unlike traditional building materials such as wood or reinforced concrete, steel frame construction offers dynamic adaptability throughout the design and production process. You can tweak panel dimensions, redesign openings, or even reconfigure load-bearing elements — all without halting production or reengineering the entire structure. This level of responsiveness becomes possible only when you combine the strength and durability of steel with the intelligence and automation of advanced manufacturing systems.

And this brings us to the real heroes of flexible construction: the steel framing rollform machines. These digitally integrated rollforming systems transform architectural drawings into high-precision structural components in a matter of minutes. Whether you’re producing standard C-studs for interior walls or complex lattice joists for large-span floors, the same machine can pivot instantly to meet demand. Want to switch from producing 89 mm studs to 150 mm joists? No problem — with the right tooling and calibration, it happens with the push of a button.

As global markets embrace off-site construction, prefab housing, and mass customization, design agility is no longer a competitive edge — it’s a survival requirement. And the companies that invest in flexible, software-driven steel framing rollform machines are the ones who will define the future of construction — not just follow it.

2. Modular Thinking: Building Blocks with Endless Possibilities

In today’s construction landscape, modern steel frame construction is not just about building strong structures — it’s about building smart. At the heart of this intelligent approach is modular thinking, a method that redefines how we conceptualize, produce, and assemble buildings.

Instead of pouring concrete on-site or measuring timber beams manually, builders now rely on modular systems where structural components — such as walls, floors, roofs, and even entire room units — are prefabricated with millimeter-level precision and then assembled like LEGO blocks. These components are no longer fixed; they’re configurable, re-usable, and adaptable. And the machine that makes this level of precision and repeatability possible is the steel framing machine.

With a flexible and software-integrated steel framing machine, each profile becomes a digital asset, part of a larger library of components that can be called upon, adjusted, or duplicated as needed. For example, a wall module used in a single-story modular classroom today can be recalibrated and reused in a double-story medical clinic tomorrow — using the exact same framing system. This kind of reusability isn’t just efficient — it’s revolutionary.

Modular steel frame construction empowers architects and builders with the ability to design once and deploy infinitely, while still retaining full creative control. The implications of this are massive, particularly for fast-moving industries like:

- Emergency response housing, where units must be deployed at scale under tight timelines

- Export-based construction, where international shipment logistics favor flat-packed, prefabricated modules

- Educational and healthcare infrastructure, which often needs to expand or relocate rapidly

- Off-grid projects, where materials must arrive complete and ready for quick on-site assembly

And let’s not forget one of the most valuable aspects of modular steel frame construction powered by steel framing machines: scalability without complexity. You can start with a base design, then scale it horizontally or vertically with minimal additional engineering. Want to add a floor? Simply introduce longer or reinforced profiles. Want to combine two units into a larger hall? Extend the floor and roof modules using mirrored designs — all generated and produced through your digital production line.

Because the entire process is driven by CAD-to-CAM (Computer-Aided Design to Computer-Aided Manufacturing) workflows, the margin for error is reduced to almost zero. Every profile is digitally optimized for:

- Structural integrity, by aligning with load-bearing demands

- Material efficiency, by minimizing steel waste and offcuts

- Assembly ease, by including all necessary holes, notches, and cutouts directly in the machine’s output

- Logistics, by packaging modules for optimized container shipping

In short, modular thinking transforms the steel framing rollform machine from a production tool into a strategic engine of scalability, customization, and operational agility. With it, steel frame construction becomes less about reacting to challenges and more about designing around opportunities.

3. Profile Variety = Design Freedom

Let’s dive into the core of what makes steel frame construction so uniquely adaptable: profile capability. While the material itself — cold-formed steel — offers inherent advantages like strength, durability, and fire resistance, the true measure of design flexibility lies in the number and diversity of profiles your steel framing machine can produce.

Think of every profile as a word in the language of architecture. The more words you know, the more fluently and creatively you can speak. Similarly, the more profiles your machine can form, the greater your architectural vocabulary — and the fewer limitations you’ll encounter during design or construction.

Modern UNBAK steel rollform framing machines are engineered with this mindset. They support a vast spectrum of dimensions, shapes, and punch configurations. Whether you’re producing frames for a 20 m² mobile clinic or a 2000 m² dormitory complex, the same machine — when properly tooled — can deliver the full range of components.

Here are some of the most common and versatile profile types UNBAK machines can produce:

- C Profiles: These are the structural backbone of most LGSF walls and roof framing systems. They’re strong, lightweight, and highly configurable.

- U Tracks: Used in floor and ceiling tracks, these profiles act as guides and anchors for wall studs.

- Z Profiles: Designed for overlapping joints or where material nesting is required — great for curtain walls and roofing overlaps.

- Sigma Profiles: Extremely strong, these are often used in industrial-grade structures or multi-story buildings where load distribution is critical.

- Lattice Joists: Ideal for open-web flooring and ceiling systems. They allow for electrical and plumbing pass-through without compromising structural performance.

Now let’s talk about the customization parameters that make these profiles so flexible:

- Web width: Machines can accommodate a wide range, typically from 70 mm to 250 mm, giving engineers the ability to scale structure sizes precisely.

- Steel thickness: Depending on the machine model and tooling, steel coils ranging from 0.8 mm up to 2.0 mm can be processed — allowing for both light-duty and heavy-duty framing.

- Punching patterns: Whether it’s service holes for cabling, dimples for strength enhancement, screw holes, notches, or embossing — all are programmable within the system.

- Flange and lip sizes: These affect the bending strength and connection integrity of profiles, and UNBAK machines allow full adjustment for each project’s needs.

What this means in practice is extraordinary. With a single advanced steel framing machine, you can support a wide spectrum of building types and applications, including but not limited to:

- Villas with long-span roof structures

- Site cabins with compact, portable frame sets

- Prefabricated cold rooms requiring thermal break design integration

- Student dormitories with repeatable modular floor plans

- Healthcare units with custom opening placements for windows, ducts, and medical systems

- Multi-story modular apartments, each floor with its own structural logic

And here’s the best part: with the help of CAD-integrated production workflows, profile parameters can be switched on the fly — meaning you can jump between job types without retooling the entire factory. One project ends at noon, another begins in the afternoon — no delays, no downtime, no compromises.

This level of profile diversity doesn’t just offer design freedom — it provides a competitive edge that enables your business to say “yes” to more clients, more tenders, and more market segments.

4. Custom Projects? No Problem. Software-Driven Steel Framing

In an era where customization is the rule, not the exception, being able to produce tailor-made building components isn’t just a luxury — it’s a necessity. Clients now expect designs that reflect unique spatial, functional, and aesthetic requirements. This means that off-the-shelf solutions and generic structural layouts are increasingly being replaced by highly personalized designs. So, how can you deliver this level of flexibility without slowing down production or increasing costs?

The answer lies in the seamless integration of steel framing machines with cutting-edge design software.

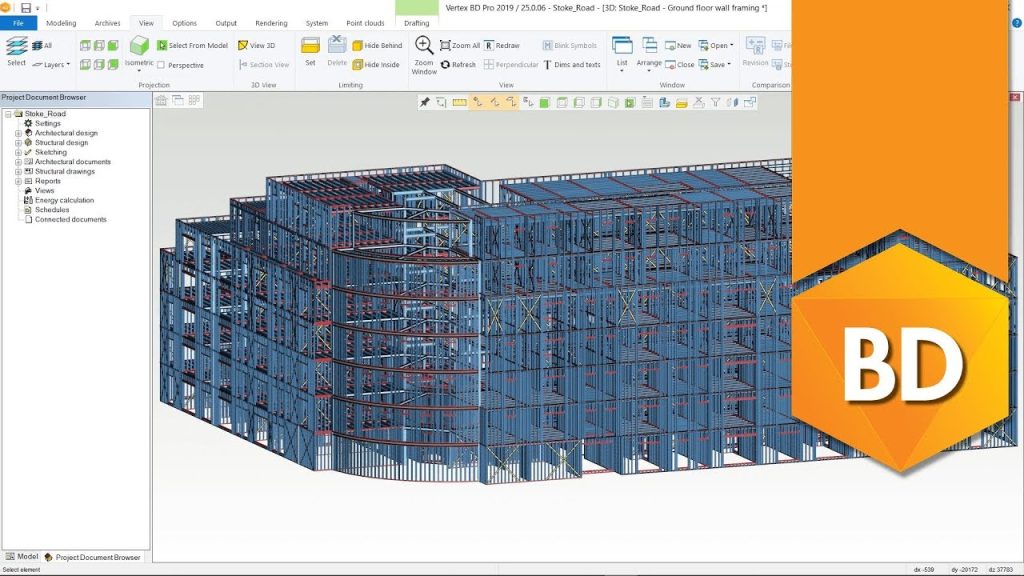

Every UNBAK steel framing machine is engineered to work in harmony with major industry-standard platforms such as Vertex BD, StrucSoft MWF (Revit plugin), and FrameBuilder MRD. These software tools empower engineers and architects to model their structures down to the smallest detail — including stud spacing, hole positioning, connector types, and fastener patterns — all within a digital environment.

Once the design is complete, it doesn’t stop at a pretty 3D model. The software exports production-ready data, usually in XML, CSV, or proprietary formats, which are directly fed into the steel framing machine. The machine processes this digital blueprint and begins producing exactly what the structure requires — no more, no less.

This level of automation enables you to:

- Generate fully custom profiles for each project, adapting geometry, punching, and cutting logic based on job-specific requirements.

- Adjust hole positions, flange sizes, service slot patterns, and cut lengths instantly based on real-time design updates.

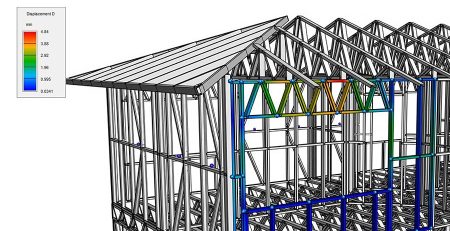

- Simulate assembly and structural behavior before production even begins, catching potential errors early in the virtual stage.

- Create part lists and material take-offs automatically, reducing procurement risks and managing inventory more efficiently.

The biggest advantage? It removes ambiguity from the steel frame construction process. Every cut, hole, and profile is exactly where it needs to be — all without human measurement or interpretation. This eliminates the most common sources of costly delays: measurement errors, incorrect punching, and field modifications.

From an operational perspective, software-driven steel frame construction also supports Just-In-Time (JIT) manufacturing. You can produce parts in the exact sequence they’ll be assembled, minimizing on-site confusion and reducing the need for storage or rehandling. For modular steel frame construction companies working across international markets, this is a huge logistical benefit — it means you can ship labeled, numbered, and ready-to-assemble frame components directly to the site, confident that everything will fit perfectly.

Moreover, this approach allows you to handle a wide variety of custom projects with the same steel framing machine. Whether it’s a student dormitory with unique corridor widths or a healthcare unit with non-standard mechanical routing, every variable can be planned, simulated, and executed digitally before the first coil is even loaded into the machine.

In short, software integration doesn’t just make production more efficient — it transforms your entire construction process into a smart, data-driven system. The result? Higher productivity, lower error margins, better client satisfaction, and an unmatched ability to say “yes” to complex and custom projects.

5. From Tiny Houses to Multi-Story Buildings: Scale Without Limits

One of the greatest advantages of modern steel frame construction is its ability to scale across vastly different project types. With a single steel framing machine, manufacturers can seamlessly transition from producing lightweight frames for compact buildings to high-load profiles for multi-story structures — all within the same production setup.

Here’s how versatile it really is:

- Tiny Houses: Lightweight, energy-efficient, and built for mobility. Steel framing machines enable precision cuts that reduce structural weight and optimize insulation cavities.

- Modular Offices: Repetitive, standardized layouts benefit from high-speed production. The same profile can be used across dozens of identical units with consistent output quality.

- Multi-Story Buildings: With the right design and load-bearing profiles, LGSF systems can support structures up to 4–5 stories high — ideal for apartments, dormitories, or commercial buildings.

- Disaster Relief Units: In emergencies, speed and adaptability are critical. Steel framing machines allow fast response by adapting designs to local conditions, materials, and logistics.

All of this can be achieved in-house, on-demand, and with minimal lead times — thanks to the automation and precision of modern steel framing machines.

6. Speed, Sustainability, and Structural Integrity

Design freedom doesn’t just empower architects — it delivers real value to the environment and end users alike.

Thanks to the digital precision of steel framing machines, material waste is reduced to a minimum. Every steel coil is processed with optimized cutting patterns, ensuring maximum yield and minimal scrap — and any leftover material is 100% recyclable. Unlike timber framing, LGSF requires no deforestation. Compared to concrete systems, it’s significantly lighter, which not only reduces foundation loads but also lowers carbon emissions during transportation and installation.

Meanwhile, rollformed steel profiles offer exceptional strength-to-weight ratios, enabling structures that are both robust and resource-efficient. When combined with modular cladding systems, factory-prepared connections, and dry construction methods, steel frame construction becomes a complete solution: fast, flexible, durable, and environmentally responsible.

7. The Role of UNBAK: Enabling the Future of Flexible Construction

At the heart of this shift toward smarter, more adaptive steel frame construction is UNBAK Machinery. With over three decades of expertise in rollforming technology, UNBAK doesn’t just deliver steel framing machines — it delivers a complete, future-ready ecosystem for modern LGSF production.

Here’s what sets UNBAK apart:

- Modular machine platforms ranging from IC-1000 to IC-5500SA

- Multi-profile tooling and automatic calibration for faster changeovers Seamless software integration and custom punch solutions End-to-end training and technical support for LGSF factories worldwide

- Onsite and mobile production capabilities with the IC-X Mobile series

By prioritizing design flexibility and machine adaptability, UNBAK enables manufacturers in over 30 countries to construct faster, smarter, and more creatively — regardless of project type or region.

Whether it’s a permanent housing development in Europe or an emergency shelter camp in Africa, UNBAK steel framing machines adjust to the project — not the other way around.

8. Flexibility is the New Standard

The future of construction isn’t rigid — it’s responsive. In an industry where timelines are tighter and expectations are higher, light gauge steel framing combined with advanced steel framing machines gives builders the power to turn creative vision into structural reality with unmatched speed and precision.

Modular? Custom? Urgent? Large scale? With the right steel framing setup, your production line can shift seamlessly — from one building type to another, from one profile to the next — without delay and without compromise.

In a world where every client expects something unique, flexibility is no longer a bonus — it’s the baseline. It’s what separates yesterday’s builders from tomorrow’s innovators. And it’s made possible by the intersection of smart design, automated manufacturing, and the unmatched versatility of cold-formed steel.

If you’re ready to build smarter, faster, and bolder — it’s time to invest not just in a machine, but in a mindset.

A mindset powered by flexibility. A mindset powered by UNBAK.

Design Flexibility Fast Production in Steel Frame Machine – Construction

Why Light Gauge Steel Framing Is the Future of Affordable Housing

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply