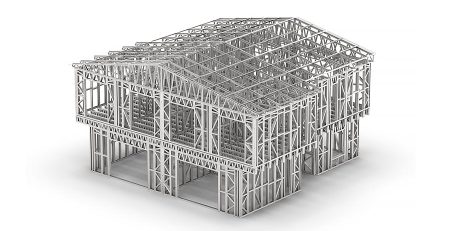

In light gauge steel framing (LGSF) systems, cladding is far more than just an aesthetic finish — it is an essential part of the building envelope that directly influences the structure’s long-term performance and resilience. While many still associate cladding with appearance or facade styling, its role in modern steel construction goes far deeper. A well-designed cladding system contributes significantly to structural stability, thermal insulation, acoustic control, fire safety, moisture management, and protection against environmental conditions such as wind, rain, and UV exposure.

In fact, in the context of prefabricated and modular steel buildings — where precision, speed, and performance are key — the cladding strategy must be engineered from the outset. Unlike traditional building methods where cladding is sometimes treated as a secondary layer, in LGSF it is fully integrated into the wall panel design. The type of materials, their arrangement, and their compatibility with the steel framing all affect the building’s energy efficiency and lifecycle cost.

The wall assembly illustrated above reflects this holistic mindset. It’s a smart, multi-layered cladding configuration optimized for use with light steel framing. Each layer has been carefully selected and arranged to serve a distinct function, from vapor control to thermal insulation and external protection. This level of integration and detail ensures that the final structure is not only visually appealing, but also meets — or exceeds — today’s performance standards in modular and cold-formed steel construction.

🧱 Layer by Layer: What Makes This Cladding System Work

In high-performance light gauge steel (LGS) construction, the wall is no longer just a passive separator between indoor and outdoor space — it’s an active system designed to control air, moisture, heat, sound, and even fire. A properly layered wall assembly in a steel framing system must take into account not only mechanical strength but also how each material contributes to the overall building envelope. This becomes especially critical in prefabricated and modular construction, where wall panels are factory-built and shipped as ready-to-install units.

The wall system shown in the diagram above is a carefully engineered multi-layer assembly — each material selected for its specific role and performance contribution. From internal vapor control to external weather shielding, every layer plays a part in ensuring that the building is safe, efficient, and built to last.

When these layers are thoughtfully combined, they don’t just protect the light steel frame — they enhance it. The synergy between insulation, framing, barriers, and cladding results in a wall system that is strong, thermally efficient, soundproof, moisture-resistant, and code-compliant. This smart integration of layers is what makes modern steel buildings not only fast to construct, but also durable and sustainable over the long term.

Let’s take a closer look at each of these layers and understand how they work together to form a robust exterior cladding solution.

Basics of Cladding in LGSF – Inside to Outside

1. Soffit Panel – Timber Cladding or Different Cladding Pattern

Timber cladding panels or other decorative wall finishes can be installed on interior walls to enhance the aesthetic appeal and improve acoustic performance. These natural materials bring warmth and texture into residential or commercial interiors, blending harmoniously with various architectural styles.

2. Vapor Barrier

Often overlooked, the vapor barrier plays a critical role in preventing condensation inside the wall cavity. By controlling vapor diffusion, it protects insulation materials and steel components from corrosion, mold, and decay. It also acts as a thermal protection mechanism, improving energy efficiency and indoor comfort.

3. Boardex Plate (A Cement-Based Fiberboard)(Optional)

A cement-based fiberboard like Boardex adds rigidity and enhances fire resistance. It’s especially beneficial in wet or high-humidity environments. If there is any level difference between floors or sections during installation, this gap can also be covered using Boardex panels, offering both a functional and aesthetic solution.

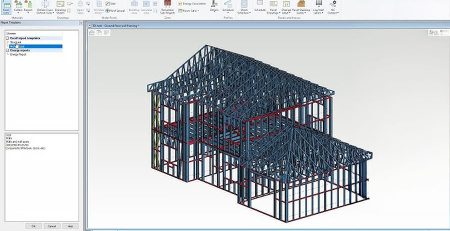

4. Light Gauge Steel Frame

This is the backbone of the structure — a precise, cold-formed steel framing system manufactured by high-tech machines like UNBAK’s IC series. It offers unmatched strength-to-weight ratio, dimensional accuracy, and fast on-site assembly.

5. 5 cm Rock Wool – 120 kg/m²

High-density mineral wool insulation provides top-notch thermal and acoustic performance. It is also non-combustible, making it ideal for fire-rated wall assemblies in both residential and commercial applications.

6. Boardex Plate (A Cement-Based Fiberboard)(Optional)

A cement-based fiberboard like Boardex adds rigidity and enhances fire resistance. It’s especially beneficial in wet or high-humidity environments. As an optional layer, it allows design flexibility depending on climate and project needs. If there is any level difference between floors or sections during installation, this gap can also be covered using Boardex panels, offering both a functional and aesthetic solution.

7. Weather-Resistant Barrier (WRB)

The WRB is the silent guardian of the wall. It prevents water penetration while allowing trapped vapor to escape, keeping inside the wall system dry and breathable. It’s essential for long-term performance of steel framing and cladding systems.

8. Metal Cladding + Foam

The outermost skin of the wall, this metal cladding serves both protective and decorative roles. Paired with integrated foam, it boosts thermal insulation and reduces thermal bridging — one of the most critical design challenges in steel construction.

🏗️ Where This Cladding System Truly Excels

This type of cladding strategy isn’t just theoretical — it’s built for real-world performance across a wide range of building types and environmental conditions. Its versatility and efficiency make it especially valuable in modern construction sectors that prioritize speed, sustainability, and resilience.

🏠 Tiny Houses & Modular Homes

In space-efficient housing, every millimeter counts. Lightweight yet high-performing cladding solutions help reduce total wall thickness without compromising insulation or structural integrity. The result? More usable interior space, better thermal comfort, and streamlined installation — especially crucial in factory-built modular housing.

🏢 Fast-Track Commercial Buildings

From retail outlets to office buildings, time is money. Pre-engineered light steel panels with integrated cladding allow developers to speed up construction timelines while meeting strict building code requirements. This cladding system offers a predictable, low-maintenance facade with excellent thermal and acoustic behavior.

🏥 Prefabricated Schools & Hospitals

Institutional buildings demand strict safety and hygiene standards — especially when it comes to fire resistance and indoor air quality. The use of rock wool insulation, WRB membranes, and metal cladding ensures compliance with fire ratings and durability, even under continuous use.

❄️ Cold Climates or Humid Zones

In regions with extreme temperature swings or high humidity, the building envelope must work harder. The vapor barrier, WRB, and dense rock wool insulation create a balanced system that resists condensation, air leakage, and mold — protecting both the structure and its occupants year-round.

Design Flexibility Fast Production in Steel Frame Machine – Construction

Why Light Gauge Steel Framing Is the Future of Affordable Housing

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply