Agriculture is at the heart of human survival. Yet with the global population projected to exceed nine billion by 2050, farmers face an unprecedented challenge: producing more food with fewer resources under increasingly unpredictable weather conditions. Traditional construction methods for greenhouses —such as timber, concrete, or PVC—are falling short in terms of durability, speed, and sustainability.

This is where light gauge steel (LGS)(Greenhouse Construction), also known as cold formed steel (CFS) in North America, enters the scene. Combined with advanced steel framing machines, LGS has become the modern backbone of greenhouse construction. Its strength, modularity, and recyclability make it a perfect match for the agricultural sector’s demand for efficiency and sustainability.

In this blog, we’ll explore why light steel is revolutionizing greenhouse construction, how steel framing machines streamline the process, and why farmers and agribusinesses are turning to modular steel solutions for the future of sustainable farming.

Why Choose Light Gauge Steel for Greenhouses?

Greenhouses must endure extreme temperature shifts, high humidity, and the constant load of ventilation, irrigation, and climate control equipment. To survive these demanding conditions while still delivering consistent performance, the choice of structural material is critical. This is where light gauge steel—also known as cold formed steel—provides clear and measurable advantages over traditional materials like timber, aluminum, or PVC.

Durability: Greenhouses built with galvanized light gauge steel can withstand decades of exposure to rain, humidity, and chemical fertilizers without structural degradation. Unlike wood, which is prone to rotting and insect damage, or aluminum, which may weaken under stress, galvanized steel maintains its strength. With the right coating, a steel greenhouse can deliver more than 30 years of uninterrupted service, making it a true long-term investment for farmers and agribusinesses.

Precision: Using advanced steel framing machines, every profile is produced with millimeter-level accuracy. This means columns, beams, and roof trusses are cut, punched, and labeled in perfect synchronization with the digital design. For greenhouse construction, precision is essential—poorly fitted joints can lead to air leaks, reduced insulation, and uneven weight distribution. Steel ensures a perfect fit, resulting in an airtight and energy-efficient structure.

Speed of Construction: Time is money in agriculture, and delays can cost an entire season’s harvest. Roll-forming technology allows thousands of profiles to be manufactured in a single day, significantly cutting down project timelines. Instead of waiting weeks for manual cutting and assembly, farmers can have their steel-framed greenhouse ready for installation in a fraction of the time, allowing them to start production sooner.

Flexibility: Greenhouses come in many forms—from compact research stations used by universities to massive industrial-scale facilities stretching across hectares. Light gauge steel framing adapts to all these scales with ease. The design software connected to steel framing machines allows customized dimensions, roof angles, and load-bearing requirements to be applied instantly. This flexibility ensures that each greenhouse is tailored to its environment, crop type, and production goals.

Low Maintenance: Unlike timber, which requires regular treatment against moisture and pests, or PVC structures that warp and weaken under UV exposure, light gauge steel greenhouses demand minimal upkeep. Farmers can focus on crop management instead of worrying about structural repairs. The galvanized coatings applied to steel provide long-lasting resistance to corrosion, saving thousands of dollars in maintenance costs over the structure’s lifespan.

Sustainability: Steel is one of the most recyclable materials on Earth, and light gauge steel profiles can be reused infinitely without losing structural integrity. This makes greenhouses built with steel an eco-friendly choice that aligns with modern environmental and climate goals. By choosing steel over disposable materials, growers reduce waste, minimize their carbon footprint, and invest in a greenhouse that supports long-term sustainable farming practices.

In short, light gauge steel provides the trifecta of strength, speed, and sustainability—qualities that are essential for modern greenhouse construction and global food security.

How Steel Framing Machines Work

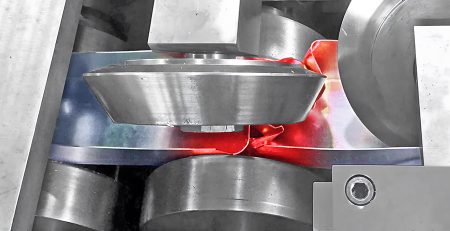

At the core of this revolution are steel framing machines, often referred to as roll forming machines. These machines convert galvanized steel coils into precise structural elements for greenhouse construction.

Design Input: Engineers feed digital designs into software that defines every detail of the greenhouse, including load-bearing requirements and environmental considerations.

Automated Processing: Steel coils are unrolled and passed through multiple forming stations.

Profile Production: Beams, studs, trusses, and bracing elements are punched, cut, and labeled automatically.

Error-Free Manufacturing: The integration between design software and roll forming ensures profiles fit perfectly on-site.

Ready-to-Assemble Kits: Produced elements are sorted, packed, and shipped as modular kits, minimizing waste and installation errors.

This seamless integration of digital design and automated production allows greenhouses to be built faster, cheaper, and with higher precision than ever before.

Types of Greenhouses and Global Applications

Greenhouses are no longer simple, one-size-fits-all structures. Modern agriculture demands flexibility, efficiency, and adaptability, and light gauge steel framing provides exactly that. With its precision, strength, and modular capabilities, it enables a wide range of greenhouse designs tailored to very specific purposes and climates.

Traditional Agricultural Greenhouses: These large-scale facilities are designed for continuous production of vegetables, fruits, and flowers. Farmers in Europe, North America, and Asia rely on steel’s long lifespan to ensure their crops are protected season after season. Unlike wooden frames, which may degrade, or PVC structures that warp, light gauge steel greenhouses remain stable and reliable, maximizing yield and reducing downtime.

Research Greenhouses: Universities, agricultural institutes, and biotech firms require controlled environments to test new crop varieties, study climate effects, and develop pest-resistant plants. Precision-built steel frames allow for airtight joints and stable temperature regulation, creating the perfect laboratory conditions needed for scientific advancement.

Hydroponic & Aquaponic Farms: These next-generation food production systems demand strong support structures to carry water tanks, circulation pipes, grow beds, and climate systems. Light steel framing provides the strength-to-weight ratio necessary to safely handle this equipment while keeping construction light enough to remain cost-effective. This makes steel the preferred choice for farmers experimenting with sustainable, soil-free agriculture.

Tropical & Desert Greenhouses: In hot and dry regions such as the Middle East, North Africa, and parts of Australia, greenhouses face severe temperature fluctuations. Light gauge steel withstands expansion and contraction caused by extreme heat, maintaining its shape and strength where other materials might fail. When combined with cooling systems and solar panels, these steel-framed structures enable year-round farming in some of the harshest climates on Earth.

Urban and Rooftop Greenhouses: Cities are increasingly turning to vertical farming and rooftop agriculture to bring food production closer to consumers. Here, lightweight but durable steel frames are critical. They provide the necessary safety and strength to support farming structures on existing buildings in cities like New York, Tokyo, and Berlin, where space is limited but demand for fresh produce is high.

From Europe’s famous flower markets in the Netherlands to large-scale desert farming projects in Saudi Arabia, and from research institutions in Canada to rooftop farms in Asia’s megacities, steel-framed greenhouses are scaling rapidly across the globe. This versatility demonstrates how light gauge steel is not only revolutionizing construction techniques but also expanding the possibilities of what greenhouses can achieve in modern agriculture.

Key Advantages of Light Gauge Steel in Greenhouse Construction

Light gauge steel does not just offer “some benefits”—it fundamentally reshapes greenhouse building. Here are the most important contributions:

1. Strength-to-Weight Ratio

Steel provides unmatched strength without excessive weight. This allows greenhouses to cover wider spans without heavy foundations, making them easier and cheaper to build—even in remote areas.

2. Engineering Precision

Every profile produced by a steel framing machine is exact. Tight joints and balanced load distribution result in higher energy efficiency and better climate control inside the greenhouse.

3. Weather Resistance

Greenhouses are often exposed to high winds, storms, or heavy snow loads. Steel maintains stability under such conditions, significantly reducing the risk of structural failure.

4. Biological Resistance

Steel is immune to mold, termites, and pests, unlike wood, which can deteriorate rapidly in humid environments.

5. Modular Expansion

Farmers can start small and expand later. Steel-framed greenhouses are modular—extensions can be added without dismantling the original structure.

6. Low Maintenance

Protective galvanization reduces corrosion risks, meaning greenhouses need minimal upkeep compared to timber or PVC alternatives.

7. Smart System Integration

Steel frames can bear additional loads from solar panels, LED grow lights, irrigation systems, and climate control equipment, making them future-proof for smart farming.

8. Sustainability

Steel is 100% recyclable. At the end of a greenhouse’s life, every component can be reused or repurposed. Unlike plastics or chemically treated wood, steel leaves behind no harmful waste.

The Advantages of Galvanized Steel in Greenhouse Construction

When it comes to greenhouse construction, not all steel is created equal. The use of galvanized light gauge steel adds a significant layer of protection and durability that makes it the preferred choice for agricultural structures.

Superior Corrosion Protection: Galvanization applies a zinc coating to the surface of the steel, which forms a barrier against rust and oxidation. This protective layer ensures that the greenhouse frame can endure decades of exposure to irrigation water, fertilizers, and changing climate conditions without structural weakening.

Moisture Resistance: Greenhouses are inherently humid environments where condensation, irrigation, and temperature shifts constantly expose the structure to moisture. Traditional materials like wood often rot or attract mold, while untreated metals corrode quickly. Galvanized steel, on the other hand, remains unaffected, delivering unmatched reliability in high-humidity agricultural settings.

Extended Service Life: Thanks to its corrosion resistance, galvanized steel extends the operational lifespan of greenhouses beyond 30 years. Farmers and investors benefit from lower lifecycle costs since they avoid frequent repairs, replacements, or structural reinforcements that are common with other materials.

Low Maintenance Requirements: Unlike timber frames that require regular chemical treatment or repainting, galvanized steel is virtually maintenance-free. Farmers can focus their time and resources on crop management and innovation rather than upkeep of the building itself.

Sustainability Benefits: By reducing the need for constant repairs or replacements, galvanized steel also minimizes material waste. Combined with the fact that steel is 100% recyclable, this makes galvanized framing a sustainable solution for the future of greenhouse construction.

In essence, galvanized light gauge steel provides the perfect balance of strength, longevity, and resistance to moisture, making it the most dependable option for building durable and efficient greenhouses worldwide.

Smart Farming and Greenhouse Technology

The future of agriculture is high-tech, and greenhouses are evolving into controlled ecosystems. Light steel frames provide the structural strength required to integrate advanced technologies, including:

Automated irrigation systems for efficient water use.

HVAC and climate control units for precision temperature management.

Renewable energy systems such as solar panels mounted on greenhouse roofs.

Vertical farming installations inside steel-framed structures for maximum yield per square meter.

By combining modular greenhouse construction with smart farming systems, farmers can produce higher yields, reduce waste, and operate sustainably year-round.

Case Studies: Greenhouses Around the World

Europe (Netherlands, Spain): Countries leading in horticulture have adopted cold formed steel greenhouses to maximize efficiency in flower and vegetable markets.

Middle East (UAE, Saudi Arabia): Extreme desert climates require durable structures with climate control—light gauge steel provides the resilience needed.

North America (USA, Canada): Urban farming and modular greenhouse projects are expanding rapidly, driven by demand for local, sustainable food sources.

Economic Benefits and ROI

Greenhouses are an investment—and light steel ensures that investment pays off:

Faster Construction = Faster Returns: Projects are completed in weeks instead of months.

Reduced Maintenance Costs: No rot, termites, or warping—less money wasted on repairs.

Long-Term Resale Value: Steel maintains structural quality and can be repurposed.

Improved Efficiency: Smart farming integration boosts yields and reduces operating costs.

Farmers and investors consistently report higher ROI with steel-framed greenhouses compared to traditional materials.

Sustainability and the Future of Greenhouses

Sustainability is not just a buzzword; it’s a necessity. Steel greenhouses support global efforts toward eco-friendly farming:

Fully Recyclable Material: Light gauge steel is one of the most sustainable construction materials in the world because it can be recycled endlessly without losing its strength or structural quality. At the end of a greenhouse’s lifecycle, every component—beams, trusses, studs—can be melted down and reformed into new steel products. This ensures that nothing goes to waste and aligns greenhouse projects with circular economy principles.

Energy Efficiency: Slim and precise steel profiles reduce the amount of shading inside the structure, allowing maximum natural sunlight to reach the crops. This minimizes the reliance on artificial lighting systems, cutting down energy costs significantly. Better daylight penetration not only saves money but also promotes healthier plant growth by maintaining a more natural photosynthetic environment.

Lower Carbon Footprint: Light steel greenhouses have both a faster construction timeline and a much longer service life compared to timber or PVC alternatives. This combination reduces the frequency of replacements, material usage, and transportation emissions. Over decades, the environmental impact of a steel-framed greenhouse is far lower, making it a smarter investment for eco-conscious farmers and agribusinesses.

Climate Resilience: Modern agriculture faces unpredictable weather—from hurricanes and high winds to heavy snow loads and extreme heat waves. Light gauge steel frames are engineered to withstand these challenges, ensuring structural safety and crop protection. By reducing the risk of greenhouse collapse or damage, steel construction provides farmers with stability, security, and peace of mind in any climate.

In the future, greenhouses will not merely protect crops—they will function as smart ecosystems powered by renewable energy and precision agriculture. Light gauge steel framing machines are the foundation of this transformation.

Farming Reinvented with Steel

The greenhouse is no longer just a glass house—it’s the central hub of modern agriculture. To meet global food demand and face climate challenges, construction methods must evolve. Light gauge steel framing machines deliver unmatched precision, durability, modularity, and sustainability.

By embracing cold formed steel and modular greenhouse construction, farmers and agribusinesses are investing not only in structures but in the future of sustainable food production.

Steel-framed greenhouses are more than buildings—they are the future of farming.

Why Light Gauge Steel Framing Is the Future of Affordable Housing

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply