The construction industry is changing fast. Traditional materials like concrete and timber can’t keep up with modern demands for speed, accuracy, and sustainability. That’s why light gauge steel framing (LGSF) — also called cold formed steel — has become the future of building.

With the right steel framing machine, you can produce entire houses, offices, or modular units in a fraction of the time it takes with conventional methods. But here’s the thing: owning a machine isn’t enough. Success in LGSF comes from strategy — understanding your design software, production flow, materials, and training.

This guide answers every key question for those who want to start light gauge steel production, buy a steel framing machine, or enter the modular construction industry the right way.

1. What Is Light Gauge Steel (LGSF)?

Light Gauge Steel Framing (LGSF) is a modern building system that uses thin, high-strength galvanized steel sheets shaped into structural profiles. Unlike heavy structural steel, LGSF elements are cold-formed, lightweight, and extremely precise. They’re used to build houses, modular units, schools, and entire multi-story buildings.

Why is it popular?

Because it’s fast, recyclable, accurate, and durable. No cracking, no termites, no rotting — just long-lasting, engineered strength.

2. What Does “Cold Formed Steel” Mean?

“Cold formed” means that steel is shaped at room temperature through rollforming instead of being hot-rolled. This process gives it high tensile strength and perfect dimensional accuracy — the secret behind light steel’s performance.

3. Is Light Gauge Steel the Same as Steel Frame Construction?

Not exactly. Structural steel is used in heavy-duty industrial buildings (I-beams, columns, etc.), while light gauge steel is used for modular and residential projects. It’s like the difference between a ship hull and an airplane body — both strong, but designed for different jobs.

4. Why Is LGSF Growing So Fast Worldwide?

Because traditional construction is slow, messy, and expensive. LGSF is:

- 4x faster than concrete building,

- 100% recyclable,

- Climate-resistant,

- And software-driven for precision and efficiency.

Governments are pushing green, modular housing — and LGSF fits perfectly into that revolution.

5. Are LGSF Buildings Accepted Worldwide?

Yes.

LGSF is recognized across Europe, the US, the Middle East, and Asia.

Many projects use local engineers to certify structures according to local codes.

6. Can I Really Build a House Entirely from Light Gauge Steel?

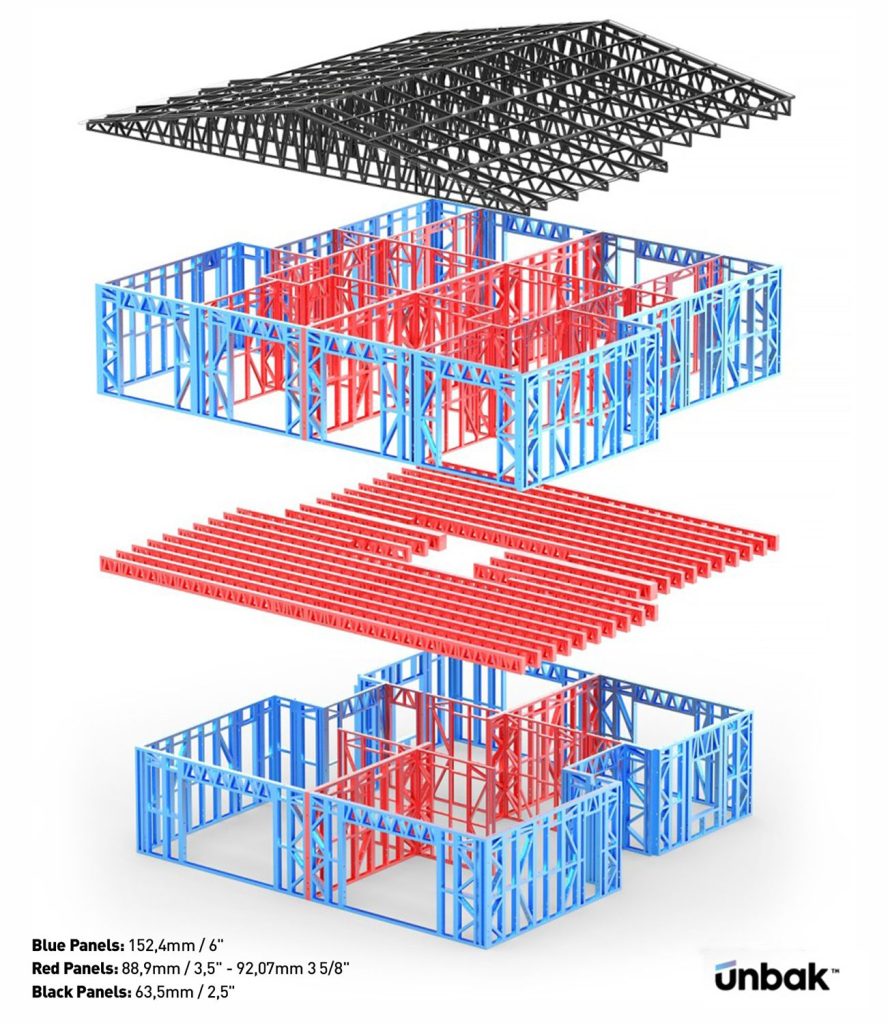

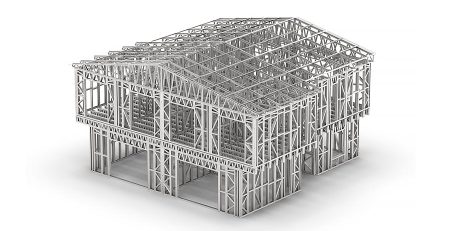

Yes — you can build a complete house, villa, or even multi-story structure entirely from light gauge steel (LGSF). Modern steel framing systems replace traditional concrete and timber with precision-formed galvanized profiles that create the entire skeleton of the building.

From walls to roof trusses, every part is pre-engineered and cut to exact dimensions by the machine. Once on site, assembly is fast, clean, and requires minimal labor. In most cases, a two-story LGSF house can be completed in just a few weeks — ready for cladding, insulation, and interior finishing.

7. Is Light Gauge Steel More Expensive Than Traditional Construction?

At first glance, the machine and steel coil investment may look higher — but in practice, LGSF construction is significantly more cost-effective.

Traditional methods like concrete or brickwork take longer, require more labor, and generate heavy on-site waste. Light gauge steel structures are designed digitally and produced automatically, which saves time, manpower, and rework costs.

When you factor in the speed of production, the lower transport costs, and the long service life of galvanized steel, LGSF buildings often reduce total project costs by 20–30% compared to concrete systems.

8. Can Light Gauge Steel Buildings Be Customized for Any Design?

Absolutely. LGSF systems are designed through specialized software, allowing architects and engineers to create fully customized structures.

The design flexibility is one of the biggest strengths of light gauge steel — you can adjust wall thickness, height, span length, and even integrate modern facades without structural compromise.

9. How Long Does It Take to Produce and Assemble a Steel Frame Building?

Production is surprisingly fast. Once your digital model is ready, a steel framing machine can produce a complete wall panel in just a few minutes.

A small residential project can be fully produced in 1–2 days of machine work, and the assembly on site often takes less than a week. Compared to concrete or brick construction — which might take months — LGSF reduces your delivery time by up to 70%.

Faster production also means faster project turnover and more flexibility for modular and prefab builders.

10. Is It Difficult to Maintain or Repair Light Gauge Steel Structures?

Not at all. One of the major advantages of light gauge steel is its low maintenance and long lifespan.

Galvanized steel does not rot, warp, or get damaged by insects like timber does. It also resists mold and corrosion thanks to its zinc coating.

In case of any structural change or damage, profiles can be easily replaced or reinforced because each part is pre-engineered and labeled.

11. Which One Is More Strong, CEment, Timber or Steel?

Cement (concrete) is strong in compression but weak in tension, which is why it always needs steel reinforcement. Timber, on the other hand, is lightweight and flexible but vulnerable to humidity, fire, and termites.

Light gauge steel (LGSF) combines the best of both worlds — it’s lightweight like timber, yet stronger and more durable than concrete when designed properly.

A properly engineered steel framing system can handle high wind loads, snow loads, and seismic activity while maintaining dimensional accuracy and long-term performance. That’s why more builders are replacing traditional materials with cold formed steel in modern modular and prefabricated construction.

12. How Strong Are LGSF Buildings?

Light gauge steel structures are engineered for strength and longevity. Every building passes through a detailed static analysis process during design, considering wind loads, snow loads, and earthquake resistance. This makes LGSF buildings not only durable but also safe in all climate and seismic conditions.

13. Are LGSF Buildings Suitable for Hot or Humid Climates?

Yes.

(Galvanized Steel and Magnalize Steel) Galvanized coating protects against rust, and steel doesn’t absorb moisture.

Perfect for tropical, coastal, or desert climates.

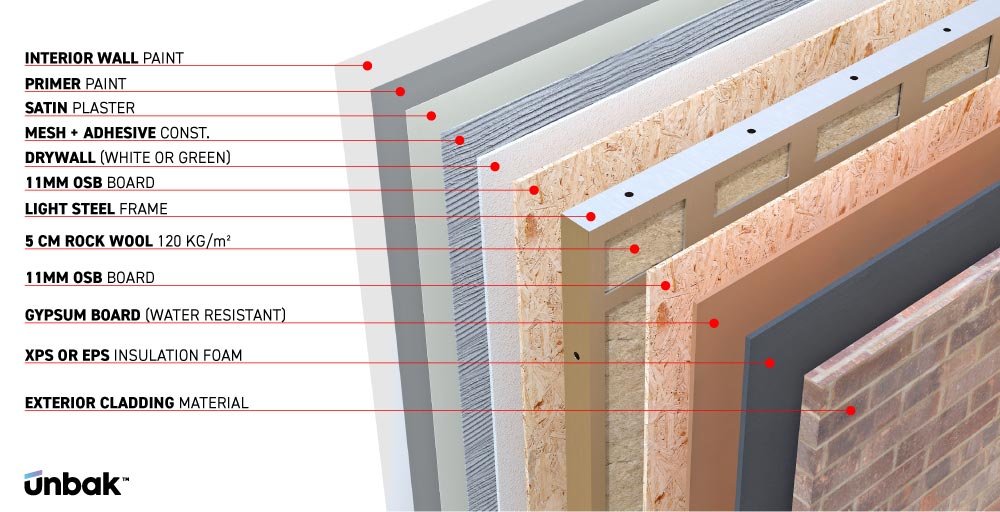

14. How Is Thermal and Sound Insulation Managed?

Insulation is placed inside wall cavities — between steel studs.

Use rock wool, glass wool, or PIR panels for high thermal and acoustic performance.

15. Can I Build Modular and Tiny Houses with LGSF?

Absolutely.

That’s one of the strongest applications of light gauge steel framing (LGSF).

Its modular and lightweight nature makes it ideal for producing tiny houses, portable buildings, container homes, and emergency shelters. The entire structure can be manufactured with precision in a controlled environment, then packed and shipped flat to the construction site.

Once delivered, panels can be assembled quickly with minimal tools and labor, without the need for heavy equipment. This flexibility allows builders to complete full-scale housing projects even in remote or off-grid locations, making LGSF one of the most versatile and efficient construction systems in the modern world.

16. What Types of Buildings Can I Produce?

- Residential houses

- Modular schools

- Hospitals and clinics

- Warehouses

- Tiny houses and holiday units

- Multi-story buildings up to 4–5 floors

17. What Is a Steel Framing Machine?

A steel framing machine (like the UNBAK ICARUS series) is the heart of production. After you design your constrcution in design softwares, Steel Framing Machines transforms flat galvanized steel coils into fully punched, labeled, and cut-to-length structural profiles.

Step by step:

- Coil is fed into the machine.

- Punch stations create service holes, dimples, and connection points.

- Rollform stations shape the steel.

- Inkjet labeling marks each part for easy assembly.

- The cut system trims the profile with precision.

18. What Are Punching Stations?

Punching stations are hydraulic modules that create holes and indentations on steel strips.

Each punch performs a specific task:

- Service holes for cables and pipes,

- Bolt holes for connections,

- Dimples to strengthen joints,

- Web Notch to make assembly easy.

- Swage or flange holes for profile alignment.

These punches are standart punches for Light Steel Profile production. There are too many differnet variations punches like Rivert Punch, Multiple-Dimple Punch, Oval Service Hole Punch…

UNBAK machines allow adding or upgrading punch stations later — thanks to the LGSFLEX system.

19. Do I Need Multiple Profile Machine?

Having a multi-profile machine is not always necessary in the steel framing process.

If your projects are single-story or you only need profiles for light applications — such as creating interior walls in concrete constructions — a single web width is sufficient.

However, if you plan to produce two-story or multi-story buildings, being able to manufacture multiple web width sizes becomes essential. It allows you to design lighter structures, optimize load distribution, and reduce the total steel cost of your project.

20. Can One Machine Produce Multiple Profile Sizes?

Yes — advanced models like UNBAK’s IC-1000SA, IC-2500SA or IC-5500SA can produce multiple web widths (60mm, 75 mm, 90mm, 100mm, 150 mm, 200 mm, 250 mm…).

Change the rollforming tools and punch cores, and the same machine can handle different project types without major reconfiguration.

21. What Is SABS (Sheet Anti-Blocking System)?

SABS is a UNBAK-exclusive innovation that prevents the coil from jamming between rollforming stations.

When steel folds like an accordion (a common nightmare in cheap machines), production stops for hours. SABS prevents that by automatically controlling sheet tension and alignment.

Result: zero downtime, zero frustration.

![]()

22. What Is the LGSFLEX System?

It’s UNBAK’s modular design philosophy — allowing customers to add new punch types or profile widths later.

You start small, expand when your business grows. No need for a brand-new machine.

23. What Kind of Steel Coils Are Used for LGSF?

Always use galvanized steel (coated with zinc for corrosion protection). These are min and max ranges of steel used in Light Steel Constructions.

Typical specs:

- Thickness: 0.60 mm – 3.0 mm

- Zinc coating: 275–350 g/m²

- Strength: G250 to G550

Avoid recycled or rusty coils — they damage punches and reduce accuracy.

24. What Are the Typical Coil Weights?

Most LGSF factories use coils of 1.5 – 3/4 tons each. This value change depends on the project and the machine you choose.

If you plan high-volume production, use a hydraulic decoiler to handle heavy coils safely.

25. How Much Space Do I Need for a Factory?

This depends on the machine and your production capacity. A compact setup fits in 600–800 m², including:

- Machine line (10–13 m length)

- Coil zone

- Output area

- Packing table

- Office room

- Assembly Area

That’s it — you don’t need a massive factory to start.

26. What About Power Requirements?

In Europian and Asian areas UNBAK machines mostly work with 380 V / 50 Hz / 3-phase power supply. This change in USA and CANADA depends on local electric demands.

If grid access is unstable, a generator works fine — even for mobile onsite production.

27. How Many Operators Do I Need?

1–3 trained people are enough:

- 1 operator using machine (loading Coil, loading project files, monitor production)

- 2 packer for profile stacking

- 2-4 for assembly (**this change depends on project deadlines and project sizes)

28. What Software Is Used for Design and Production?

LGSF relies on specialized software that converts building designs into machine-readable data:

- Vertex BD

- FrameBuilder MRD

- Strucsoft MWF

These generate .CSV or .XML files that the machine reads to punch, cut, and label automatically.

Also other softwares like Tekla and others are suitable for LGSF design.

29. What Happens If the Software File Has Errors?

Then your profiles will be wrong.

Every cut, hole, and dimple is software-driven — precision depends on clean data.

That’s why UNBAK provides software training and testing before real production.

30. How Does Labeling Work?

Each profile is printed with an inkjet label showing:

- ID number

- Project name

This makes on-site assembly as easy as following LEGO instructions.

31. What Maintenance Does the Machine Need?

UNBAK Machines has Maintance chart which indicates Daily, Weekly, Mounthly, Yearly Maintance. By this way you can easly check and do the maintance form Check list.

Some Examples of Daily Check:

General: Lubricate all sliding and moving parts

Production: Check the Calibration on profile

Production: Check tool offset by runnig a sample

Production: Check Flange Straightness

Production: Check Production for Twist and bow

Electrical: Check Functionality of Emergency Stops

De-Coiler: Check Functionalityof Emergency Stops of Decoiler

Punch Sets: Clean Swage punch with air pressure gun

UNBAK’s design allows fast maintenance without stopping the entire line.

32. What Should I Do If the Coil Jams?

If you have SABS, it won’t happen.

If not, stop immediately, release the pressure manually, and call service.

33. How Does UNBAK’s After-Sales Support Work?

UNBAK offers Three Levels of Service Support. Each level provides a different type of assistance depending on the complexity and nature of the problem.

First Average response time: 5–30 minutes. (In First Level, First Contact is Online)

Support includes:

- Remote troubleshooting

- Software assistance

- On-site visits if necessary

- Machine Online Health Diagnose

Real support, not automated chatbots.

34. Do I Need Training to Operate the Machine?

Yes, and you’ll get it.

UNBAK provides installation + training at your facility or remotely.

Training usually takes between 1 to 3 days, depending on the operator’s experience and the machine model.

35. Can the Operator Handle Both Machine and Software?

Machine production software and construction design software serve different purposes. The customer requires an architect for structural design and an operator to manage production and operate the machine accordingly.

36. What Are Common Beginner Mistakes?

- Choosing the wrong coil thickness.

- Over-estimating early profits.

- Hiring untrained operators.

- Buying cheap machines from trading companies.

- Buying machines that is not suitable for their projects.

- Buying machines that has no service support of lack of service support.

Avoid these, and you’ll save months of frustration.

36. Can I Start Small and Expand Later?

Definitely.

You can start with a single-profile machine and upgrade to multi-profile or mobile systems later or you can start with smaller machines and then you can move to biggger machines. But at this stage please keep in minde that buying machine is an long term deicion.

UNBAK machines are modular by design.

37. How Much Does a Steel Framing Machine Cost?

Prices vary by model:

- IC-1000 / IC-1000SA → for single or multiple web width (Entry)

- IC-2000S / IC-2500SA→ for single or multiple web width (Pro)

- IC-3500SA → for single or multiple web width + higher flange + floor joist (Pro)

- IC-5500SA → for single or multiple web width + higher flange X 2 Flange or more + floor joist (H.Pro)

- IC-XMOBILE → mobile containerized factory

38. How Do I Calculate ROI for LGSF?

Add:

- Machine cost

- Coil + operation cost per ton

- Local construction rate per m²

Even small operations can profit with 1–2 medium houses per month.

39. What Types of Buildings Can I Produce?

- Residential houses

- Modular schools

- Hospitals and clinics

- Warehouses

- Tiny houses and holiday units

- Multi-story buildings up to 4–5 floors

40. What Is UNBAK IC-XMOBILE?

It’s a factory inside a container — machine, decoiler, generater, and workbench all integrated.

Ideal for remote regions, military zones, or off-grid projects. IC-XMOBILE supports only 1000-2000Series machines and max 1.6 Steel Thickness.

You can start producing directly on-site — plug the generator, load the coil, and build.

41. How Does On-Site Production Work?

The machine inside the container runs the same as a stationary one.

Profiles are produced directly next to the construction area — reducing transport cost and time.

It’s production freedom.

42. Can It Work Without Electricity?

Yes, with a generator setup.

UNBAK XMOBILE is fully compatible with independent power sources — true off-grid construction.

43. How Can I Ensure My Profiles Meet Structural Requirements?

Use quality steel, calibrated tools, and approved software.

UNBAK provides test profiles and structural reports during commissioning.

44. What Testing Should I Perform Before Selling or Exporting?

- Profile dimensions

- Punch position accuracy

- Cut angle

- Zinc coating thickness

Once validated, you’re ready for international projects.

45. What About Spare Parts?

UNBAK supplies all spare parts directly from stock.

Punch tools, rollers, and sensors are shipped within days — no long waiting.

46. Can I Get Custom Punch Designs?

Yes.

You can design your own punch patterns; UNBAK manufactures them.

Thanks to the Slide & Lock system, you can replace punch cores in minutes.

47. How Is Quality Control Done?

Every profile’s dimensions and holes are checked with digital calipers and verified with software drawings.

Before shipment, every UNBAK machine is thoroughly tested with all profile dimensions and various production variations to ensure perfect accuracy and performance.

48. Can I Visit UNBAK’s Factory Before Buying?

Of course.

You can see live production in Izmir / Turkey, inspect machines under assembly, and discuss custom configurations directly with engineers.

49. What Makes UNBAK Different from Trading Companies?

UNBAK designs and manufactures everything in-house with his 35 Years of High Tech Custom Rollforming Experience.

CNC precision, R&D innovations (like SABS & LGSFLEX & 3 STAGE CUT), and lifetime service — that’s what makes UNBAK stand apart.

Every UNBAK steel framing machine is fully tested with all profile sizes and production variations before delivery, guaranteeing precision, consistency, and reliability from the first day of use.

51. What’s the Future of LGSF Construction?

Automation, mobility, and sustainability.

As global housing demand explodes, LGSF will become the default method for modern construction — faster, cleaner, and smarter.

52. Why Choose UNBAK Machinery?

Because experience matters.

With over 34 years of rollforming expertise, UNBAK Machinery CO LTD leads the industry with machines like:

- IC-1000 Series → 1.2mm Steel Thickness, Compact Size, Single or Multiple Web Width Options, Lattice joist.

- IC-2000 Series → 1.6mm Steel Thickness, Single or Multiple Web Width Options, Lattice joist.

- IC-3000 Series → 2.5mm Steel Thickness, Single or Multiple Web Width Options, Single Flange Height Options, Lattice Joist + Floor Joist.

- IC-5500SA Series → 2.5mm Steel Thickness, Single or Multiple Web Width Options, Single or Multiple Flange Height Options, Lattice Joist + Floor Joist.

- IC-XMOBILE → On-site, containerized production. Supports Only 1000 and 2000 SERIES Machines.

Light gauge steel framing is not just another construction trend — it is the foundation of a faster, cleaner, and more sustainable future. With digital design integration, automated production, and advanced rollforming technology, LGSF allows builders to achieve accuracy and efficiency that traditional methods can’t match.

But true success doesn’t come from the machine alone — it comes from understanding the process, the materials, and the technology behind every profile. That’s why UNBAK Machinery doesn’t just manufacture steel framing machines; it delivers complete, future-ready production systems built on more than three decades of rollforming expertise.

Whether you’re starting a new factory, expanding your business, or entering modular construction for the first time, UNBAK gives you the precision, training, and long-term reliability you need to lead the next generation of building.

Handbook for Light Gauge Steel Structure Production – How LGS Done?

Step-by-Step Guide to the Construction of Light Gauge Steel Structures: Click

Sound and Thermal Insulation in Light Gauge Steel Structures: Click

UNBAK Youtube Video List: Click

Leave a Reply